Общий каталог Dijet 2018 - страница 360

Навигация

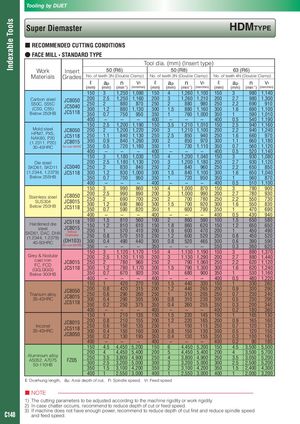

Indexable Tools Tooling by DIJET Super Diemaster HDMTyPE ■ RECOMMENDED CUTTING CONDITIONS ● FACE MILL • STANDARD TYPE Tool dia. (mm) (Insert type) Work Insert 50 (R6) 50 (R8) 63 (R6) Materials Grades No. of teeth 3N (Double Clamp) No. of teeth 3N (Double Clamp) No. of teeth 4N (Double Clamp) ℓ ap n Vf ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) 150 3 1,250 1,090 150 4 1,260 1,100 150 3 980 1,140 Carbon steelS50C, S55C(C50, C55)Below 250HBJC8050JC5040JC51182002503003502.51,2501,16028808701.28801,1300.775095020025030035031,2601,21020028809802501.58801,16030017601,0003502.72.21.619801,3006909106901,1005901,010 400 – – – 400 – – – 400 0.5 540 1,190 150 2.5 1,200 1,190 150 3.5 1,210 1,010 150 2.5 940 1,160 Mold steel JC8050 200 2 1,200 1,220 200 3 1,210 1,100 200 2.2 940 1,240 HPM7, PX5,NAK80, P20(1.2311, P20)30-43HRCJC5118250JC8015300For over 40HRC3501.10.90.58401,1302502.58401,26030027201,18035018509402508509703007301,1103501.61.10.76609706601,1805601,120 400 – – – 400 – – – 400 0.5 520 1,140 150 3 1,180 1,030 150 4 1,200 1,040 150 3 930 1,080 Die steel 200 2.5 1,180 1,130 200 3 1,200 1,180 200 2.7 930 1,120 SKD61, SKD11 JC5040 250 2 830 840 250 2 840 960 250 2.2 650 850 (1.2344, 1.2379) JC5118 300 1.2 830 1,000 300 1.5 840 1,100 300 1.6 650 1,040 Below 255HB 350 0.7 700 950 350 1 720 950 350 1 560 870 400 – – – 400 – – – 400 0.5 510 1,100 150 3 990 860 150 4 1,000 870 150 3 780 900 Stainless steelSUS304Below 250HBJC8050JC8015JC51182002503003502.521.20.7990890 200 3 1,000 990 20069070025027007802506908603001.570092030059082035016007903502.72.21.61780930550730550830470690 400 – – – 400 – – – 400 0.5 430 940 Hardened die JC5118steelJC8015SKD61, DAC, DHAWithoutChipbreaker(1.2344, 1.2379)40-50HRC(DH103)1001502002503001.51.210.80.481056010028106101501.85704102001.65705102501.24904403000.88605901008606201506004702006005202505204653001.51.210.80.6650580650650450490450520390590 (For over 50HRC) 350 – – – 350 – – – 350 0.3 360 620 150 3 1,120 1,170 150 4 1,130 1,190 150 3 880 1,370 Grey & Nodular 200 2.5 1,120 1,110 200 3 1,130 1,290 200 2.7 880 1,440 cast ironFC, FCD(GG,GGG)Below 300HBJC8015250JC511830035021.20.7780960 250 27801,1703001.567092035017901,0602507901,3003006809003502.21.616201,1206201,2405301,160 400 – – – 400 – – – 400 0.5 480 1,220 150 1 420 270 150 1.5 440 330 150 1 330 260 Titanium alloy35-43HRCJC8050JC8015JC5118 2002503003500.80.60.40.2420315 200 1.229026025012903053000.82503753500.44402652003102052503102303002602553500.90.70.50.3330290230240230295200340 400 – – – 400 – – – 400 0.2 180 360 150 1 210 135 150 1.5 220 145 150 1 165 130 Inconel35-43HRCJC8015JC5118JC8050 2002503003500.80.60.40.2210155 200 1.215013525011501603000.81301953500.42201652001501152501501303001301553500.90.70.50.3165160120130120150100165 400 – – – 400 – – – 400 0.2 90 180 150 4.5 4,450 5,200 150 6 4,450 5,200 150 4.5 3,500 5,500 200 4 4,450 5,400 200 5 4,450 5,400 200 4 3,500 5,700 Aluminium alloyA5052, A7075FZ0550-110HB 250 3.5 3,800 4,900 250 43002.53,2005,00030033501.53,1004,20035023,8004,9002503,2005,0003003,1004,2003503.53,0505,2002.52,5005,2001.52,4004,300 400 1 2,550 3,000 400 1 2,550 3,000 400 1 2,000 3,200 ℓ: Overhung length, ap: Axial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. C148 3) If machine does not have enough power, recommend to reduce depth of cut first and reduce spindle speedand feed speed.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском