Общий каталог Dijet 2018 - страница 344

Навигация

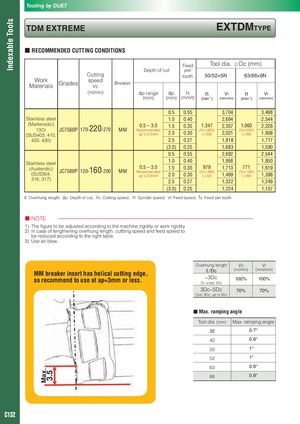

Indexable Tools Max. 3.5 Tooling by DIJET TDM EXTREME EXTDMTyPE ■ RECOMMENDED CUTTING CONDITIONS Feed Tool dia. φDc (mm) Depth of cut per Cutting tooth 50/52×5N 63/66×6N WorkMaterialsGrades speedVc Breaker (m/min) ap range ap fz n Vf n Vf (mm) (mm) (mm/t) (min-1) (mm/min) (min-1) (mm/min) 0.5 0.55 3,704 3,498 Stainless steel 1.0 0.40 2,694 2,544 (Martensitic)13CrJC7560P170-220-270 MM(SUS403, 410,0.5 – 3.0 1.5Recommendedup to 2.5mm2.00.351,3472,357 1,060 2,2260.30(Vc=220)(φ52)2,021(Vc=220)(φ66)1,908 420, 430) 2.5 0.27 1,818 1,717 (3.0) 0.25 1,683 1,590 0.5 0.55 2,692 2,544 Stainless steel 1.0 0.40 1,958 1,850 (Austenitic)(SUS304,JC7560P120-160-200 MM 0.5 – 3.0 1.5Recommendedup to 2.5mm2.00.359791,713 771 1,6190.30(Vc=160)(φ52)1,469(Vc=160)(φ66)1,388 316, 317) 2.5 0.27 1,322 1,249 (3.0) 0.25 1,224 1,157 ℓ: Overhung length, ap: Depth of cut, Vc: Cutting speed, n: Spindle speed, Vf: Feed speed, fz: Feed per tooth ■ NOTE 1) The figure to be adjusted according to the machine rigidity or work rigidity. 2) In case of lengthening overhung length, cuttting speed and feed speed to be reduced according to the right table. 3) Use air blow. Overhung length Vc Vf MM breaker insert has helical cutting edge, ℓ / Dc (m/min) (mm/min) so recommend to use at ap=3mm or less. ~3Dc 100% 100%Or under 3Dc 3Dc~5Dc 70% 70% Over 3Dc, up to 5Dc ■ Max. ramping angle Tool dia. (mm) Max. ramping angle 32 0.7° 40 0.8° 50 1° 52 1° 63 0.8° 66 0.8° C132

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском