Общий каталог Dijet 2018 - страница 337

Навигация

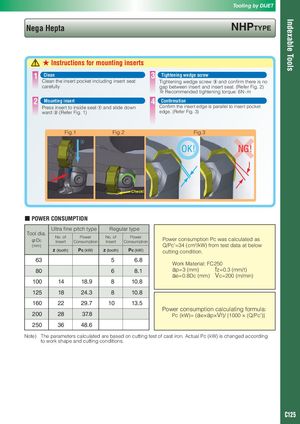

Indexable Tools Tooling by DIJET Nega Hepta NHPTYPE ★ Instructions for mounting inserts 1 Clean 3 Tightening wedge screw Clean the insert pocket including insert seat Tightening wedge screw ③ and confirm there is no carefully gap between insert and insert seat. (Refer Fig. 2) ※ Recommended tightening torque: 6N · m 2 Mounting insert 4 Confirmation Press insert to inside seat ① and slide down Confirm the insert edge is parallel to insert pocket ward ② (Refer Fig. 1) edge. (Refer Fig. 3) Fig.1 Fig.2 Fig.3 ② OK! NG! ③ ① Check! ■ POWER CONSUMPTION Ultra fine pitch type Regular type Tool dia. No. of Power No. of PowerφDcInsertConsumptionInsertConsumptionPower consumption Pc was calculated as (mm) Q/Pc'=34 (cm3/kW) from test data at below z (tooth) Pc (kW) z (tooth) Pc (kW) cutting condition. 63 5 6.8 Work Material: FC250 80 6 8.1 ap=3 (mm) fz=0.3 (mm/t) ae=0.8Dc (mm) Vc=200 (m/min) 100 14 18.9 8 10.8 125 18 24.3 8 10.8 160 22 29.7 10 13.5 Power consumption calculating formula: 200 28 37.8 Pc (kW)= (ae×ap×Vf)/ {1000 × (Q/Pc')} 250 36 48.6 Note) The parameters calculated are based on cutting test of cast iron. Actual Pc (kW) is changed according to work shape and cutting conditions. C125

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском