Общий каталог Dijet 2018 - страница 338

Навигация

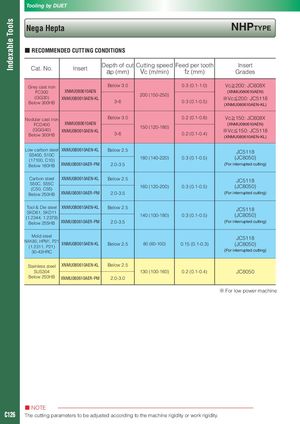

Indexable Tools Tooling by DIJET Nega Hepta nHPTyPE ■ RECOMMENDED CUTTING CONDITIONS Cat. No. Insert Depth of cut Cutting speed Feed per toothap (mm)Vc (m/min)fz (mm)InsertGrades Grey cast iron Below 3.0 0.3 (0.1-1.0) Vc≧200: JC608X FC300 XNMU080610AEN(GG30)XNMU080610AEN-KLBelow 300HB3-6200 (150-250)0.3 (0.1-0.5) (XNMU080610AEN)※Vc≦200: JC5118(XNMU080610AEN-KL) Nodular cast iron Below 3.0 0.2 (0.1-0.8) Vc≧150: JC608X FCD400 XNMU080610AEN(GGG40)XNMU080610AEN-KLBelow 300HB3-6 (XNMU080610AEN)150 (120-180)0.2 (0.1-0.4)※Vc≦150: JC5118(XNMU080610AEN-KL) Low carbon steel XNMU080610AEN-KL Below 2.5SS400, S10C(17100, C10)180 (140-220)0.3 (0.1-0.5) JC5118(JC8050) Below 180HB XNMU080610AER-PM 2.0-3.5 (For interrupted cutting) Carbon steel XNMU080610AEN-KL Below 2.5S50C, S55C(C50, C55)160 (120-200)0.3 (0.1-0.5) JC5118(JC8050) Below 250HB XNMU080610AER-PM 2.0-3.5 (For interrupted cutting) Tool & Die steel XNMU080610AEN-KL Below 2.5SKD61, SKD11(1.2344, 1.2379)140 (100-180)0.3 (0.1-0.5)JC5118(JC8050) Below 255HB XNMU080610AER-PM 2.0-3.5 (For interrupted cutting) Mold steelNAK80, HPM1, P21(1.2311, P21)XNMU080610AEN-KLBelow 2.580 (60-100)0.15 (0.1-0.3) JC5118(JC8050) 30-43HRC (For interrupted cutting) Stainless steel XNMU080610AEN-KL Below 2.5 SUS304 130 (100-160) 0.2 (0.1-0.4) JC8050 Below 250HB XNMU080610AER-PM 2.0-3.0 ※ For low power machine ■ NOTE C126 The cutting parameters to be adjusted according to the machine rigidity or work rigidity.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском