Общий каталог Dijet 2018 - страница 266

Навигация

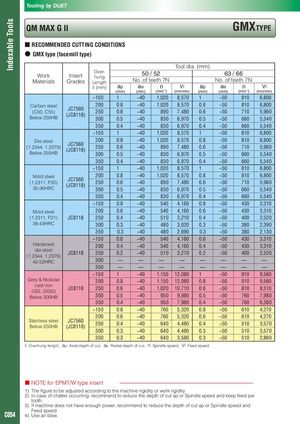

Indexable Tools Tooling by DIJET QM MAX G II GMXTYPE ■ RECOMMENDED CUTTING CONDITIONS ● GMX type (facemill type) Tool dia. (mm) Over-WorkInserthungMaterialsGradesLength50 / 52No. of teeth 7N 63 / 66No. of teeth 7N ℓ (mm) ap ae n Vf ap ae n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) ~150 1 ~40 1,020 8,570 1 ~50 810 6,800 Carbon steel(C50, C55)Below 250HBJC7560(JC8118)2002503000.80.60.5~40 1,020 8,570 0.8~408907,4800.6~408306,9700.5~50~50~508106,8007105,9606605,540 350 0.4 ~40 830 6,970 0.4 ~50 660 5,540 ~150 1 ~40 1,020 8,570 1 ~50 810 6,800 Die steel(1.2344, 1.2379)Below 255HBJC7560(JC8118)2002503000.80.60.5~401,020 8,570 0.8~408907,4800.6~408306,9700.5~50~50~508106,8007105,9606605,540 350 0.4 ~40 830 6,970 0.4 ~50 660 5,540 ~150 1 ~40 1,020 8,570 1 ~50 810 6,800 Mold steel(1.2311, P20)30-36HRCJC7560(JC8118)2002503000.80.60.5~40 1,020 8,570 0.8~408907,4800.6~408306,9700.5~50~50~508106,8007105,9606605,540 350 0.4 ~40 830 6,970 0.4 ~50 660 5,540 ~150 0.8 ~40 540 4,160 0.8 ~50 430 3,310 Mold steel 200 0.6 ~40 540 4,160 0.6 ~50 430 3,310 (1.2311, P21) JC8118 250 0.4 ~40 510 3,210 0.4 ~50 400 2,520 38-43HRC 300 0.3 ~40 480 3,020 0.3 ~50 380 2,390 350 0.3 ~40 480 2,690 0.3 ~50 380 2,130 ~150 0.6 ~40 540 4,160 0.6 ~50 430 3,310 Hardened 200 0.4 ~40 540 4,160 0.4 ~50 430 3,310 die steel(1.2344, 1.2379)JC8118250 0.2 ~40 510 3,210 0.2 ~50 400 2,520 42-52HRC 300 — — — — — — — — 350 — — — — — — — — ~150 1 ~40 1,150 12,080 1 ~50 910 9,560 Grey & Nodular 200 0.8 ~40 1,150 12,080 0.8 ~50 910 9,560 cast iron(GG, GGG)JC8118 250 0.6 ~40 1,020 10,710 0.6 ~50 810 8,510 Below 300HB 300 0.5 ~40 950 9,980 0.5 ~50 760 7,980 350 0.4 ~40 950 7,980 0.4 ~50 760 6,380 ~150 0.8 ~40 760 5,320 0.8 ~50 610 4,270 200 0.6 ~40 760 5,320 0.6 ~50 610 4,270 Stainless steel JC7560Below 250HB(JC8118)2500.4 ~40 640 4,480 0.4 ~50 510 3,570 300 0.3 ~40 640 4,480 0.3 ~50 510 3,570 350 0.3 ~40 640 3,580 0.3 ~50 510 2,860 ℓ: Overhung length, ap: Axial depth of cut, ae: Radial depth of cut, n: Spindle speed, Vf: Feed speed ■ NOTE for EPMT/W type insert 1) The figure to be adjusted according to the machine rigidity or work rigidity. 2) In case of chatter occurring, recommend to reduce the depth of cut ap or Spindle speed and keep feed per tooth. 3) If machine does not have enough power, recommend to reduce the depth of cut ap or Spindle speed and C054 Feed speed.4)Use air blow.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском