Общий каталог Dijet 2018 - страница 200

Навигация

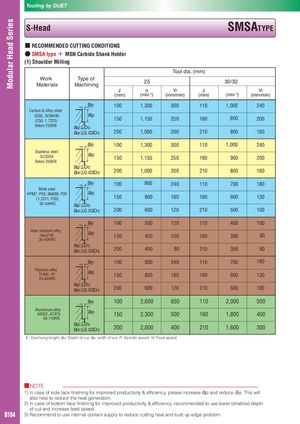

Modular Head Series Tooling by DIJET S-Head SMSATYPE ■ RECOMMENDED CUTTING CONDITIONS ● SMSA type + MSN Carbide Shank Holder (1) Shoulder Milling Tool dia. (mm) Work Type ofMaterialsMachining 25 30/32 ℓ n Vf ℓ Vf (mm) (min-1) (mm/min) (mm) (min-1) (mm/min) ae 100 1,300 300 110 1,000 240 Carbon & Alloy steel S50C, SCM440(C50, 1.7223) ap 150 1,150 250 160 900 200 Below 250HB ap≦Dc ae≦0.03Dc 200 1,000 200 210 800 160 ae 100 1,300 300 110 1,000 240 Stainless steelSUS304 ap 150 1,150 250 160 900 200 Below 250HB ap≦Dc ae≦0.03Dc 200 1,000 200 210 800 160 ae 100 900 240 110 700 180 Mold steelHPM7, PX5, NAK80, P20(1.2311, P20)ap150 800 180 160 600 130 30-43HRC ap≦Dc ae≦0.03Dc 200 600 120 210 500 100 ae 100 500 120 110 400 100 Heat resistant alloyInco718 ap 150 450 100 160 380 90 35-43HRC ap≦Dcae≦0.03Dc 200 400 80 210 350 80 ae 100 900 240 110 700 180 Titanium alloyTi-6AL-4V ap 150 800 180 160 600 130 35-43HRC ap≦Dcae≦0.03Dc 200 600 120 210 500 100 ae 100 2,600 650 110 2,000 500 Aluminium alloyA5052, A7075ap 150 2,300 500 160 1,800 400 50-110HB ap≦Dcae≦0.03Dc 200 2,000 400 210 1,600 300 ℓ: Overhung length, ap: Depth of cut, ae: width of cut, n: Spindle speed, Vf: Feed speed ■NOTE 1) In case of side face finishing for improved productivity & efficiency, please increase ap and reduce ae. This will also help to reduce the heat generation. 2) In case of bottom face finishing for improved productivity & efficiency, recommended to use lower (shallow) depth of cut and increase feed speed. B184 3) Recommend to use internal coolant supply to reduce cutting heat and built up edge problem.

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском