Общий каталог Dijet 2018 - страница 201

Навигация

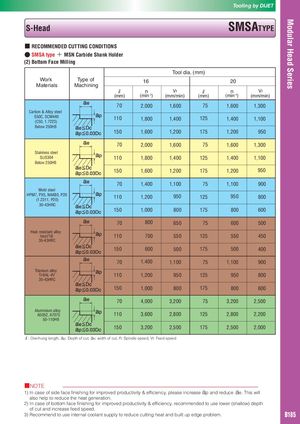

Modular Head Series Tooling by DIJET S-Head SMSATYPE ■ RECOMMENDED CUTTING CONDITIONS ● SMSA type + MSN Carbide Shank Holder (2) Bottom Face Milling Tool dia. (mm) Work Type of 16 20 Materials Machining ℓ n Vf ℓ n Vf (mm) (min-1) (mm/min) (mm) (min-1) (mm/min) 70 2,000 1,600 75 1,600 1,300 Carbon & Alloy steel S50C, SCM440(C50, 1.7223) 110 1,800 1,400 125 1,400 1,100 Below 250HB 150 1,600 1,200 175 1,200 950 70 2,000 1,600 75 1,600 1,300 Stainless steel SUS304 110 1,800 1,400 125 1,400 1,100 Below 250HB 150 1,600 1,200 175 1,200 950 70 1,400 1,100 75 1,100 900 Mold steel HPM7, PX5, NAK80, P20(1.2311, P20) 110 1,200 950 125 950 800 30-43HRC 150 1,000 800 175 800 600 70 800 650 75 600 500 Heat resistant alloy Inco718 110 700 550 125 550 450 35-43HRC 150 600 500 175 500 400 70 1,400 1,100 75 1,100 900 Titanium alloy Ti-6AL-4V 110 1,200 950 125 950 800 35-43HRC 150 1,000 800 175 800 600 70 4,000 3,200 75 3,200 2,500 Aluminium alloy A5052, A7075 110 3,600 2,800 125 2,800 2,200 50-110HB 150 3,200 2,500 175 2,500 2,000 ℓ: Overhung length, ap: Depth of cut, ae: width of cut, n: Spindle speed, Vf: Feed speed ■NOTE 1) In case of side face finishing for improved productivity & efficiency, please increase ap and reduce ae. This will also help to reduce the heat generation. 2) In case of bottom face finishing for improved productivity & efficiency, recommended to use lower (shallow) depth of cut and increase feed speed. 3) Recommend to use internal coolant supply to reduce cutting heat and built up edge problem. B185

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском