Общий каталог Dijet 2018 - страница 167

Навигация

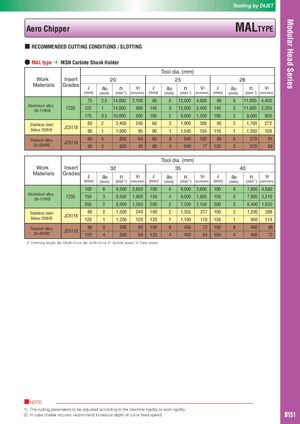

Modular Head Series Tooling by DIJET Aero Chipper MALTYPE ■ RECOMMENDED CUTTING CONDITIONS / SLOTTING ● MAL type + MSN Carbide Shank Holder Tool dia. (mm) Work Insert 20 25 28 Materials Grades ℓ ap n Vf ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) 75 2.5 14,000 2,100 90 8 12,000 4,800 90 6 11,000 4,400 Aluminium alloy50-110HBFZ05 125 1 14,000 980 140 6 12,000 2,400 140 3 11,000 2,200 175 0.5 10,000 500 190 2 9,000 1,200 190 2 9,000 900 Stainless steelBelow 250HB 60 2JC51189012,400 240 601,9009590 2 1,900 380 9011,54015411021,700 27211,350108 Titanium alloy35-43HRC 60 6JC5118903800 64 60 8 640 102 90 6 570 918004090464077120357068 Tool dia. (mm) Work Insert 32 35 40 Materials Grades ℓ ap n Vf ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) 100 6 9,500 3,800 100 6 9,000 3,600 100 8 7,800 4,680 Aluminium alloy50-110HBFZ05 150 3 9,500 1,900 150 4 9,000 1,800 150 5 7,800 3,510 200 2 8,000 1,280 200 2 7,200 1,150 200 3 6,400 1,920 Stainless steelBelow 250HB 90JC511812021 1,500 240 1001,200120120 2 1,355 217 10011,100110150211,200 288950114 Titanium alloy35-43HRC 90 8JC51181204500 80 100 8 450 72 100 85006012044505415044009640072 ℓ:Overhung length, ap: Depth of cut, ae: width of cut, n: Spindle speed, Vf: Feed speed ■NOTE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 2) In case chatter occurrs, recommend to reduce depth of cut or feed speed. B151

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском