Общий каталог Dijet 2018 - страница 168

Навигация

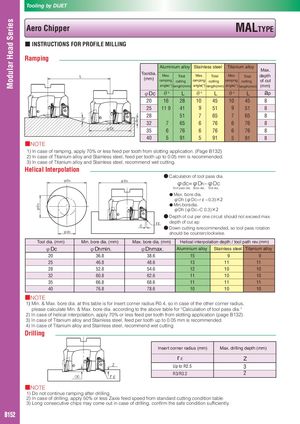

Modular Head Series φD C ap Tooling by DIJET Aero Chipper MALTYPE ■ INSTRUCTIONS FOR PROFILE MILLING Ramping Aluminium alloy Stainless steel Titanium alloy Max. L Tooldia.(mm) Max.rampingTotalcutting Max. TotalrampingcuttingMax.Totalrampingcuttingdepthof cut angle(°) length(mm) angle(°) length(mm) angle(°) length(mm) (mm) φDc θ° L θ° L θ° L ap 20 16 28 10 45 10 45 8 25 11 9 41 9 51 9 51 8 28 51 7 65 7 65 8 θ° 32 7 65 6 76 6 76 8 φDC 35 6 76 6 76 6 76 8 40 5 91 5 91 5 91 8 ■NOTE 1) In case of ramping, apply 70% or less feed per tooth from slotting application. (Page B132) 2) In case of Titanium alloy and Stainless steel, feed per tooth up to 0.05 mm is recommended. 3) In case of Titanium alloy and Stainless steel, recommend wet cutting. Helical Interpolation ● Calculation of tool pass dia. φD h φD h φdc=φDh−φDc Tool pass dia. Bore dia. Tool dia. ● Max. bore dia. φDh (φDc−rε−0.3)×2 ● Min.boredia. φDh (φDc−C 0.3)×2 ● Depth of cut per one circuit should not exceed max. rε depth of cut ap C ● Down cutting isrecommended, so tool pass rotation φdC should be counterclockwise. Tool dia. (mm) Min. bore dia. (mm) Max. bore dia. (mm) Helical interpolation depth / tool path rev.(mm) φDc φDhmin. φDhmax. Aluminium alloy Stainless steel Titanium alloy 20 36.8 38.6 15 9 9 25 46.8 48.6 13 11 11 28 52.8 54.6 12 10 10 32 60.8 62.6 11 10 10 35 66.8 68.6 11 11 11 40 76.8 78.6 10 10 10 ■NOTE 1) Min. & Max. bore dia. at this table is for insert corner radius R0.4, so in case of the other corner radius, please calculate Min. & Max. bore dia. according to the above table for “Calculation of tool pass dia.“ 2) In case of helical interpolation, apply 70% or less feed per tooth from slotting application (page B132). 3) In case of Titanium alloy and Stainless steel, feed per tooth up to 0.05 mm is recommended. 4) In case of Titanium alloy and Stainless steel, recommend wet cutting Drilling Insert corner radius (mm) Max. drilling depth (mm) rε Z Z Up to R2.5 3 (X) rε R3/R3.2 2 ■NOTE 1) Do not continue ramping after drilling. 2) In case of drilling, apply 50% or less Zaxis feed speed from standard cutting condition table. 3) Long consecutive chips may come out in case of drilling, confirm the safe condition sufficiently. B152

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском