Каталог ARNO монолитный осевой инструмент - страница 269

Навигация

Каталог ARNO инструмент для токарной обработки 2018

Каталог ARNO инструмент для токарной обработки 2018 Каталог ARNO концевые твердосплавные фрезы AFV

Каталог ARNO концевые твердосплавные фрезы AFV Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы

Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы Каталог ARNO обработка канавок и отрезка 2018

Каталог ARNO обработка канавок и отрезка 2018 Каталог ARNO инструмент для обработки отверстий 2016

Каталог ARNO инструмент для обработки отверстий 2016 Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

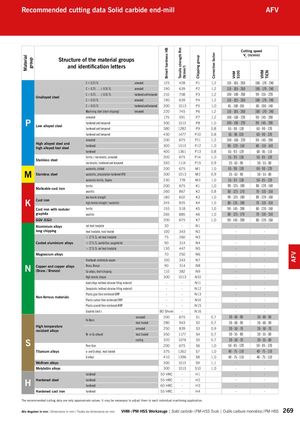

Material group Brinell hardness HB Tensile strength Rm (N/mm²) Chipping group Correction factor VHM S100 VHM TiCN AFV Recommended cutting data Solid carbide end-mill AFV Cutting speed Structure of the material groups Vc (m/min) and identification letters C ≤ 0.25 % annealed 125 428 P1 1,2 110 - 185 - 260 100 - 170 - 240 C > 0.25 … ≤ 0.55 % annealed 190 639 P2 1,2 110 - 185 - 260 100 - 170 - 240 C > 0.25 … ≤ 0.55 % hardened and tempered 210 708 P3 1,2 100 - 180 - 260 90 - 155 - 220 Unalloyed steel C > 0.55 % annealed 190 639 P4 1,2 110 - 185 - 260 100 - 170 - 240 C > 0.55 % hardened and tempered 300 1013 P5 1,0 65 - 108 -150 60 - 100 - 140 Machining steel (short-chipping) tempered 220 745 P6 1,2 110 - 185 - 260 100 - 170 - 240 annealed 175 591 P7 1,2 100 - 160 - 220 90 - 145 - 200 P Low alloyed steel hardened and temperedhardened and tempered 300 1013 P8 1,0 100 - 160 - 220 90 - 145 - 2003801282P90,865 - 98 - 13060 - 90 - 120 hardened and tempered 430 1477 P10 0,8 65 - 98 -130 60 - 90 - 120 annealed 200 675 P11 1,2 100 - 160 - 220 90 - 145 - 200 High alloyed steel andhigh alloyed tool steelhardened 300 1013 P12 1,0 90 - 120 - 150 80 - 110 - 140 hardened 400 1361 P13 0,8 65 - 93 - 120 60 - 85 - 110 ferritic / martensitic, annealed 200 675 P14 1,0 55 - 93 - 130 50 - 85 - 120 Stainless steel martensitic, hardened and tempered 330 1114 P15 0,9 35 - 63 - 90 30 - 55 - 80 austenitic, chilled 200 675 M1 1,0 65 - 98 - 130 60 - 90 - 120 M Stainless steel austenitic, precipitation-hardened (PH) 300 1013 M2 0,9 35 - 63 - 90 30 - 55 - 80 austenitic-ferritic, Duplex 230 778 M3 1,0 55 - 93 - 130 50 - 85 - 120 ferritic 200 675 K1 1,0 90 - 135 - 180 80 - 120 - 160 Malleable cast iron pearlitic 260 867 K2 0,8 80 - 125 - 170 70 - 110 - 150 low tensile strength 180 602 K3 1,0 90 - 135 - 180 80 - 120 - 160 K Cast iron high tensile strength / austenitic 245 825 K4 1,0 80 - 135 - 190 70 - 110 - 150 Cast iron with nodular ferritic 155 518 K5 1,0 90 - 145 - 200 80 - 120 - 160 graphite pearlitic 265 885 K6 1,0 80 - 125 - 170 70 - 110 - 150 GGV (CGI) 200 675 K7 1,0 90 - 145 - 200 80 - 120 - 160 Aluminium alloys not heat treatable 30 - N1 - - long chipping heat treatable, heat treated 100 343 N2 - - ≤ 12 % Si, not heat treatable 75 260 N3 - - Casted aluminium alloys ≤ 12 % Si, aushärtbar, ausgehärtet 90 314 N4 - - > 12 % Si, not heat treatable 130 447 N5 - - Magnesium alloys 70 250 N6 - - Unalloyed, elektrolyte copper 100 343 N7 - - N Copper and copper alloys(Brass / Bronze)Brass, BronzeCu-alloys, short-chipping 90 314 N8 - -110382N9-- High-tensile, Ampco 300 1013 N10 - - Lead alloys (without abrasive filling material) - - N11 - - Duroplastic (without abrasive filling material) - - N12 - - Plastic glas fibre reinforced GFRP - - N13 - - Non-ferrous materials Plastic carbon fibre reinforced CFRP - - N14 - - Plastic aramid fibre reinforced AFRP - - N15 - - Graphite (tech.) 80 Shore - N16 - - annealed 200 675 S1 0,7 30 - 60 - 90 30 - 60 - 90 Fe-Basis heat treated 280 943 S2 0,7 30 - 60 - 90 30 - 60 - 90 High temperatureresistant alloys annealed 250 839 S3 0,9 30 - 50 - 70 30 - 50 - 70 Ni- or Co-alloyed heat treated 350 1177 S4 0,7 30 - 55 - 80 30 - 55 - 80 S casting 320 1076 S5 0,7 30 - 50 - 70 30 - 55 - 80Pure titan200675S61,050 - 85 - 12050 - 85 - 120 Titanium alloys α- and β-alloys, heat treated 375 1262 S7 1,0 40 - 75 - 110 40 - 75 - 110 β-alloys 410 1396 S8 1,0 40 - 75 - 110 40 - 75 - 110 Wolfram alloys 300 1013 S9 1,1 - - Molybdän alloys 300 1013 S10 1,0 - - hardened 50 HRC - H1 - - H Hardened steel hardenedhardened 55 HRC - H2 - -60 HRC-H3-- Hardened cast iron hardened 55 HRC - H4 - - The recommended cutting data are only approximate values. It may be necessary to adjust them to each individual machining application. Alle Angaben in mm / Dimensions in mm / Toutes les dimensions en mm VHM- / PM-HSS Werkzeuge | Solid carbide- / PM-HSS Tools | Outils carbure monobloc / PM-HSS 269