Каталог ARNO инструмент и сменные пластины для токарной обработки и обработки резьбы - страница 453

Навигация

Tensile strength [N/mm2] AM15C AM5015 AM5025 AM5110 AM5120 AM5120+ AM5220 AP5210 Recommended Cutting Data Turning – High Positive Inserts coated Cutting speed Vc [m/min] ISO Material ca. 0,15% C 350 220 - 320 220 - 320 180 - 280 220 - 350 220 - 320 180 - 280 180 - 280 220 - 370 Unalloyed steel and cast steel ca. 0,45% C 650 180 - 250 180 - 290 160 - 250 180 - 310 180 - 290 160 - 250 160 - 250 180 - 330 ca. 0,75% C 1000 140 - 200 150 - 250 120 - 220 150 - 270 150 - 250 120 - 220 120 - 220 150 - 290 600 180 - 250 180 - 280 160 - 250 180 - 300 180 - 280 - 160 - 250 180 - 320 P Low alloyed steel and cast steel 900 160 - 220 170 - 250 140 - 230 170 - 270 170 - 250 - 140 - 230 170 - 2901200140 - 200150 - 220120 - 200150 - 240150 - 220-120 - 200150 - 260 High alloyed steel, high alloyed annealed 700 140 - 230 80 - 160 70 - 150 80 - 180 80 - 160 - 70 - 150 80 - 180 tool steel and cast steel hardened and tempered 1100 110 - 200 40 - 130 35 - 120 40 - 140 40 - 130 - 35 - 120 40 - 150 ferritic / martensitic, annealed 700 170 - 260 60 - 180 50 - 160 40 - 180 40 - 150 50 - 160 50 - 160 40 - 140 Stainless steel and cast steel martensitic, hardened and tempered 1000 110 - 200 40 - 140 40 - 140 40 - 160 40 - 130 40 - 140 40 - 140 40 - 120 M Stainless steel and cast steel austenitic and austenitic/ferriticchilled 450 - 600 210 - 250 80 - 160 70 - 150 80 - 180 80 - 160 70 - 150 70 - 150 70 - 150600 - 900100 - 17040 - 13035 - 12040 - 14040 - 13035 - 12035 - 12035 - 120 pearlitic, ferritic 500 - 700 210 - 250 180 - 300 180 - 300 180 - 350 180 - 300 180 - 300 180 - 300 180 - 350 Cast iron pearlitic, martensitic 700 - 850 90 - 130 160 - 280 160 - 280 160 - 300 160 - 280 160 - 280 160 - 280 160 - 300 800 - 1100 90 - 130 120 - 240 120 - 240 120 - 270 120 - 240 120 - 240 120 - 240 120 - 270 K Cast iron with nodular graphite ferritic 550 210 - 250 140 - 230 130 - 210 140 - 230 140 - 230 - 140 - 230 140 - 230 pearlitic 800 90 - 130 120 - 170 110 - 150 120 - 170 120 - 170 - 120 - 170 120 - 170 ferritic 450 210 - 250 150 - 210 130 - 200 150 - 210 150 - 210 - 150 - 210 150 - 210 Malleable cast iron pearlitic 750 90 - 130 150 - 210 130 - 200 150 - 210 150 - 210 - 150 - 210 150 - 210 not heat treatable 200 - - - - - - - - Aluminum alloys, long chipping heat treatable, heat treated 350 - - - - - - - - ≤ 12% Si, hardened 250 - - - - - - - - Casted aluminum alloys ≤ 12% Si, heat treatable, heat treated 300 - - - - - - - - ≤ 12% Si, not heat treatable 450 - - - - - - - - N Copper and copper alloys Lead alloys, Pb > 1%Brass, bronze 400 - 200 - 500 200 - 400 200 - 650 200 - 500 150 - 500 - -300-200 - 500200 - 400200 - 650200 - 500150 - 500-- (brass / bronze) Aluminum bronze 500 - 160 - 450 160 - 400 160 - 350 160 - 450 120 - 400 - - Copper and electrolyte copper 200 - 100 - 320 100 - 300 120 - 220 100 - 320 120 - 250 - - Duroplastics - 160 - 600 - 160 - 600 160 - 600 - - - Non-ferrous materials Reinforced plastics - 100 - 300 - 100 - 300 100 - 300 100 - 300 - - Hard rubber - - - - 80 - 250 - - - Fe-alloyed annealed 700 - 20 - 60 20 - 60 20 - 70 20 - 60 20 - 60 20 - 60 20 - 70 Fe-alloyed hardened 950 - 20 - 60 20 - 60 20 - 70 20 - 60 20 - 60 20 - 60 20 - 70 High temperature resistant alloys Ni- oder Co- based annealed 800 - 15 - 50 15 - 50 15 - 60 15 - 50 15 - 50 15 - 50 15 - 60 S Ni- oder Co- based casting 1100 - 15 - 40 15 - 40 15 - 50 15 - 40 15 - 40 15 - 40 15 - 50 Ni- oder Co- based hardened 1200 - 15 - 40 15 - 40 15 - 50 15 - 40 15 - 40 15 - 40 15 - 50Titanium alloys, high strengthPure titanium500 - 700-90 - 18090 - 170100 - 21090 - 180---i Alpha- and beta-alloys, hardened 700 - 1000 - 40 - 80 35 - 70 40 - 90 40 - 80 - - - hardened and tempered 1000 - 1350 - 30 - 50 30 - 50 - 30 - 50 - - - Hardened steel H Hard cast iron hardened and tempered 1350 - 1700 - 10 - 25 10 - 25 - 10 - 25 - - -casting1350-40 - 7040 - 70-40 - 70--- Hardened cast iron hardened and tempered 1900 - 10 - 25 10 - 25 - 10 - 25 - - - The datas cutting speeds given are approximate values. More grades on the It is necessary to adjust them to the individual machining operation. following pages. ARNO®-Werkzeuge | Drehen | Turning | Точение 453

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015

Каталог ARNO фрезы и сменные пластины для фрезерной обработки 2015 Каталог ARNO инструмент для обработки отверстий 2016

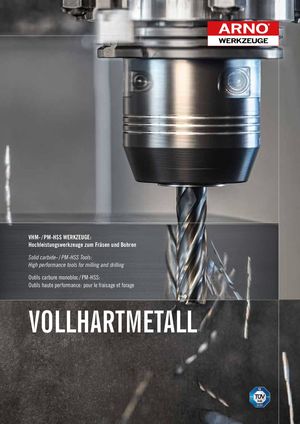

Каталог ARNO инструмент для обработки отверстий 2016 Каталог ARNO монолитный осевой инструмент

Каталог ARNO монолитный осевой инструмент Каталог ARNO оснастка для автоматов продольного точения

Каталог ARNO оснастка для автоматов продольного точения Каталог ARNO тиски станочные

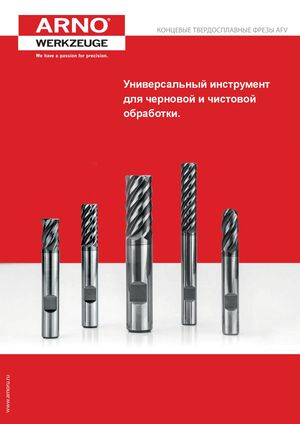

Каталог ARNO тиски станочные Каталог ARNO концевые твердосплавные фрезы AFV

Каталог ARNO концевые твердосплавные фрезы AFV