Общий каталог Yamawa 2021 - страница 700

Навигация

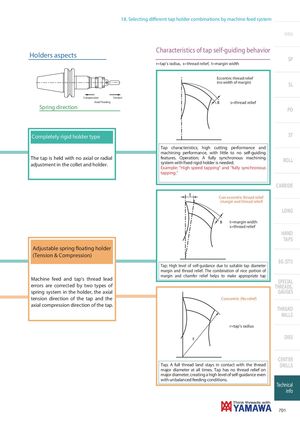

18. Selecting different tap holder combinations by machine feed system Intro Characteristics of tap self-guiding behavior Holders aspects SP r=tap’s radius, s=thread relief, t=margin width Eccentric thread relief (no width of margin) SL Compression Tension Axial Floating s=thread relief Spring direction PO Completely rigid holder type ST Tap characteristics; high cutting performance and machining performance, with little to no self-guiding The tap is held with no axial or radialadjustment in the collet and holder. features. Operation; A fully synchronous machiningsystem with fixed rigid holder is needed.ROLLExample: "High speed tapping" and "fully synchronous tapping." CARBIDE Con-eccentric thread relief (margin and thread relief) LONG t=margin width s=thread relief HAND TAPS Adjustable spring floating holder (Tension & Compression) EG (STI) Tap; High level of self-guidance due to suitable tap diameter margin and thread relief. The combination of nice portion of Machine feed and tap's thread lead margin and chamfer relief helps to make appropriate tap SPECIAL errors are corrected by two types of THREADS, spring system in the holder, the axial GAUGES tension direction of the tap and the Concentric (No relief) axial compression direction of the tap. THREAD MILLS r=tap’s radius DIES CENTER Tap; A full thread land stays in contact with the thread DRILLS major diameter at all times. Tap has no thread relief on major diameter, creating a high level of self-guidance even with unbalanced feeding conditions. Technical info 701

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали