Общий каталог Yamawa 2021 - страница 701

Навигация

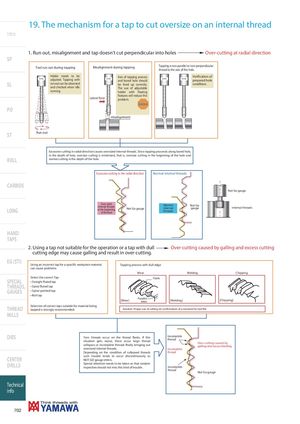

19. The mechanism for a tap to cut oversize on an internal thread Intro 1. Run out, misalignment and tap doesn’t cut perpendicular into holes Over-cutting at radial direction SP Tool run out during tapping Misalignment during tapping Tapping a non-parallel or non-perpendicularthread to the axis of the hole. Holder needs to be Axis of tapping process Verification of holder adjusted. Tapping with holder and bored hole should holder holder prepared hole SL run out can be observedand checked when idle be lined up correctly.Theuseofadjustable condition. running. holder with floating features will reduce this Lateral force problem. Solutions PO misalignment ST Run out Excessive cutting in radial direction causes oversized internal threads. Since tapping proceeds along bored hole, in the depth of hole, oversize cutting is minimized, that is, oversize cutting in the beginning of the hole and ROLL normal cutting in the depth of the hole. Excessive-cutting in the radial direction Normal internal threads CARBIDE Not Go gauge LONG Over sizedinternal threadsat the beginning Not Go gaugeof the bore Normal Not Gointernalgaugethreads internal threads HAND TAPS 2. Using a tap not suitable for the operation or a tap with dull Over-cutting caused by galling and excess cutting cutting edge may cause galling and result in over-cutting. EG (STI) Using an incorrect tap for a specific workpiece material Tapping process with dull edge can cause problems Wear Welding Chipping Select the correct Tap Flank SPECIAL • Straight fluted tap THREADS, • Spiral fluted tap GAUGES • Spiral pointed tap • Roll tap [Wear] Parallelwear [Welding] [Chipping] THREAD Selection of correct taps suitable for material beingtapped is strongly recommended. Solution: Proper use of cutting oil, confirmation of a constant for tool life MILLS DIES Torn threads occur on the thread flanks. If thissituationgetsworse,thereoccurlargethreadcollapses or incomplete threads finally bringing outIncompletethreadOver-cutting caused bygalling and excess feeding oversized internal threads. Incomplete Depending on the condition of collapsed threads thread such trouble tends to occur discontinuously as CENTER NOT-GO gouge enters. DRILLS Special attention needs to be taken so that randominspection should not miss this kind of trouble. Incomplete thread Not Go gauge Technical info 702

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали