Общий каталог Yamawa 2021 - страница 699

Навигация

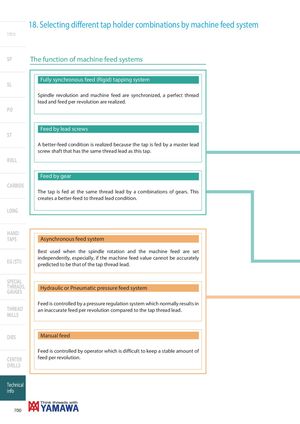

18. Selecting different tap holder combinations by machine feed system Intro SP The function of machine feed systems Fully synchronous feed (Rigid) tapping system SL Spindle revolution and machine feed are synchronized, a perfect thread lead and feed per revolution are realized. PO Feed by lead screws ST A better-feed condition is realized because the tap is fed by a master lead screw shaft that has the same thread lead as this tap. ROLL Feed by gear CARBIDE The tap is fed at the same thread lead by a combinations of gears. This creates a better-feed to thread lead condition. LONG HAND TAPS Asynchronous feed system Best used when the spindle rotation and the machine feed are set EG (STI) independently, especially, if the machine feed value cannot be accuratelypredicted to be that of the tap thread lead. SPECIAL THREADS,GAUGES Hydraulic or Pneumatic pressure feed system Feed is controlled by a pressure regulation system which normally results in THREAD an inaccurate feed per revolution compared to the tap thread lead. MILLS DIES Manual feed Feed is controlled by operator which is difficult to keep a stable amount of CENTER feed per revolution. DRILLS Technical info 700

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали