Основной каталог Winstar 2021 - страница 701

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

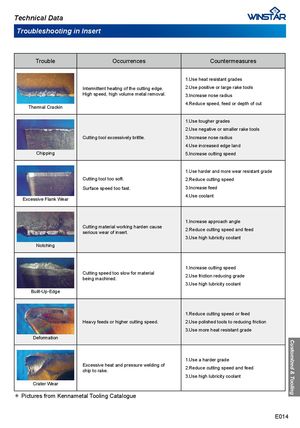

Technical Data Troubleshooting in Insert Trouble Occurrences Countermeasures 1.Use heat resistant grades Intermittent heating of the cutting edge. 2.Use positive or large rake tools High speed, high volume metal removal. 3.Increase nose radius Thermal Crackin 4.Reduce speed, feed or depth of cut 1.Use tougher grades 2.Use negative or smaller rake tools Cutting tool excessively brittle. 3.Increase nose radius 4.Use increased edge land Chipping 5.Increase cutting speed 1.Use harder and more wear resistant grade Cutting tool too soft. 2.Reduce cutting speed Surface speed too fast. 3.Increase feed Excessive Flank Wear 4.Use coolant 1.Increase approach angle Cutting material working harden causeserious wear of insert.2.Reduce cutting speed and feed 3.Use high lubricity coolant Notching 1.Increase cutting speed Cutting speed too slow for materialbeing machined.2.Use friction reducing grade 3.Use high lubricity coolant Built-Up-Edge 1.Reduce cutting speed or feed Heavy feeds or higher cutting speed. 2.Use polished tools to reducing friction 3.Use more heat resistant grade Deformation 1.Use a harder grade Excessive heat and pressure welding ofchip to rake.2.Reduce cutting speed and feed 3.Use high lubricity coolant Crater Wear ✽ Pictures from Kennametal Tooling Catalogue E014 Customized & Tooling

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020