Основной каталог Winstar 2021 - страница 700

Навигация

- Cover

- A-Milling

- Solid Carbide Endmills

- H700

- H680

- H650

- H600

- G550

- V470

- G450

- V530

- V520

- M500

- Hypex

- A300

- A200

- A100

- CuttingData

- Milling Inserts

- Indexable Milling Cutters

- Shoulder Milling Cutters

- Face Milling Cutters

- Copy Milling Cutters

- Chamgering & Engraving Cutters

- Helical Milling Cutters

- Disc Milling Cutters

- Modular Milling Tools

- B-Holemaking

- Solid Carbide Drills

- DPC&DPN

- DLC&DLN

- DMC&DMN

- DHN

- DFN

- DZC&DZN

- DAN

- DGN

- CuttingData

- Modular Drills

- Indexable Drills

- Spotting & Centering Drills

- Solid Carbide Reamers

- Indexable Boring Tools

- C-Turning

- ISO Turning Inserts

- Turning Holders

- Parting & Grooving Tools

- Mini Turning Tools for Auto Lathe

- D-Threading

- Solid Thread Mills

- Solid Thread Turning Bars

- Indexable Thread Turning Tools

- E-Customized & Tooling

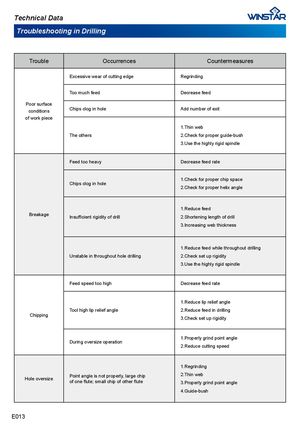

Technical Data Troubleshooting in Drilling Trouble Occurrences Countermeasures Excessive wear of cutting edge Regrinding Too much feed Decrease feed Poor surface conditions Chips clog in hole Add number of exit of work piece 1.Thin web The others 2.Check for proper guide-bush 3.Use the highly rigid spindle Feed too heavy Decrease feed rate 1.Check for proper chip space Chips clog in hole 2.Check for proper helix angle 1.Reduce feed Breakage Insufficient rigidity of drill 2.Shortening length of drill 3.Increasing web thickness 1.Reduce feed while throughout drilling Unstable in throughout hole drilling 2.Check set up rigidity 3.Use the highly rigid spindle Feed speed too high Decrease feed rate 1.Reduce lip relief angle Tool high lip relief angle 2.Reduce feed in drilling Chipping 3.Check set up rigidity 1.Properly grind point angle During oversize operation 2.Reduce cutting speed 1.Regrinding Hole oversize Point angle is not properly, large chipof one flute; small chip of other flute2.Thin web3.Properly grind point angle 4.Guide-bush E013

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020