Общий каталог Winstar 2015 - 2016 - страница 37

Навигация

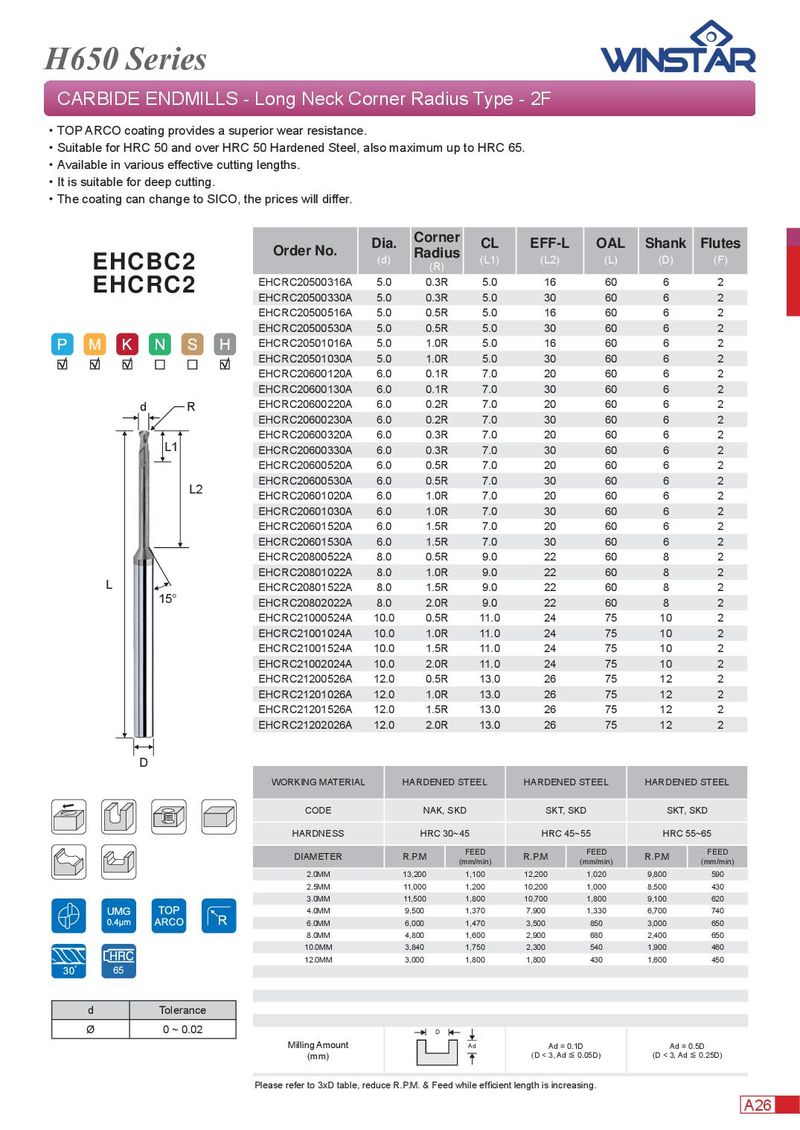

H650 Series CARBIDE ENDMILLS - Long Neck Corner Radius Type - 2F . TOP ARCO coating provides a superior wear resistance. . Suitable for HRC 50 and over HRC 50 Hardened Steel, also maximum up to HRC 65. . Available in various effective cutting lengths. . It is suitable for deep cutting. . The coating can change to SICO, the prices will differ. Corner Dia. CL EFF-L OAL Shank Flutes Order No. Radius (d) (L1) (L2) (L) (D) (F) EHCBC2 (R) EHCRC20500316A 5.0 0.3R 5.0 16 60 6 2 EHCRC2 EHCRC20500330A 5.0 0.3R 5.0 30 60 6 2 EHCRC20500516A 5.0 0.5R 5.0 16 60 6 2 EHCRC20500530A 5.0 0.5R 5.0 30 60 6 2 EHCRC20501016A 5.0 1.0R 5.0 16 60 6 2 EHCRC20501030A 5.0 1.0R 5.0 30 60 6 2 EHCRC20600120A 6.0 0.1R 7.0 20 60 6 2 EHCRC20600130A 6.0 0.1R 7.0 30 60 6 2 d R EHCRC20600220A 6.0 0.2R 7.0 20 60 6 2 EHCRC20600230A 6.0 0.2R 7.0 30 60 6 2 EHCRC20600320A 6.0 0.3R 7.0 20 60 6 2 L1 EHCRC20600330A 6.0 0.3R 7.0 30 60 6 2 EHCRC20600520A 6.0 0.5R 7.0 20 60 6 2 EHCRC20600530A 6.0 0.5R 7.0 30 60 6 2 L2 EHCRC20601020A 6.0 1.0R 7.0 20 60 6 2 EHCRC20601030A 6.0 1.0R 7.0 30 60 6 2 EHCRC20601520A 6.0 1.5R 7.0 20 60 6 2 EHCRC20601530A 6.0 1.5R 7.0 30 60 6 2 EHCRC20800522A 8.0 0.5R 9.0 22 60 8 2 EHCRC20801022A 8.0 1.0R 9.0 22 60 8 2 L EHCRC20801522A 8.0 1.5R 9.0 22 60 8 2 15° EHCRC20802022A 8.0 2.0R 9.0 22 60 8 2 EHCRC21000524A 10.0 0.5R 11.0 24 75 10 2 EHCRC21001024A 10.0 1.0R 11.0 24 75 10 2 EHCRC21001524A 10.0 1.5R 11.0 24 75 10 2 EHCRC21002024A 10.0 2.0R 11.0 24 75 10 2 EHCRC21200526A 12.0 0.5R 13.0 26 75 12 2 EHCRC21201026A 12.0 1.0R 13.0 26 75 12 2 EHCRC21201526A 12.0 1.5R 13.0 26 75 12 2 EHCRC21202026A 12.0 2.0R 13.0 26 75 12 2 D WORKING MATERIAL HARDENED STEEL HARDENED STEEL HARDENED STEEL CODE NAK, SKD SKT, SKD SKT, SKD HARDNESS HRC 30~45 HRC 45~55 HRC 55~65 FEED FEED FEED DIAMETER R.P.M (mm/min) R.P.M (mm/min) R.P.M (mm/min) 2.0MM 13,200 1,100 12,200 1,020 9,800 590 2.5MM 11,000 1,200 10,200 1,000 8,500 430 3.0MM 11,500 1,800 10,700 1,800 9,100 620 4.0MM 9,500 1,370 7,900 1,330 6,700 740 6.0MM 6,000 1,470 3,500 850 3,000 650 8.0MM 4,800 1,600 2,900 680 2,400 650 10.0MM 3,840 1,750 2,300 540 1,900 460 12.0MM 3,000 1,800 1,800 430 1,600 450 65 d Tolerance Ø 0 ~ 0.02 D Milling Amount Ad Ad = 0.1D Ad = 0.5D (mm) (D < 3, Ad ≦ 0.05D) (D < 3, Ad ≦ 0.25D) Please refer to 3xD table, reduce R.P.M. & Feed while effi cient length is increasing. A26

Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar сверление

Каталог Winstar сверление Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021 Основной каталог Winstar 2021

Основной каталог Winstar 2021