Каталог Winstar инструмент со сменными пластинами 2020 - страница 60

Навигация

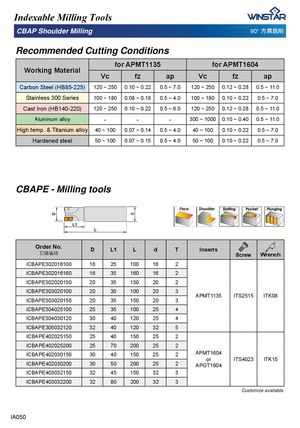

Indexable Milling Tools CBAP Shoulder Milling 90° 㝈券搠⏙ Recommended Cutting Conditions for APMT1135 for APMT1604 Working Material Vc fz ap Vc fz ap Carbon Steel (HB85-225) 120 ~ 250 0.10 ~ 0.22 0.5 ~ 7.0 120 ~ 250 0.12 ~ 0.28 0.5 ~ 11.0 Stainless 300 Series 100 ~ 180 0.08 ~ 0.18 0.5 ~ 4.0 100 ~ 180 0.10 ~ 0.22 0.5 ~ 7.0 Cast Iron (HB140-220) 120 ~ 250 0.10 ~ 0.22 0.5 ~ 6.0 120 ~ 250 0.12 ~ 0.28 0.5 ~ 11.0 Aluminum alloy - - - 300 ~ 1000 0.10 ~ 0.40 0.5 ~ 11.0 High temp. & Titanium alloy 40 ~ 100 0.07 ~ 0.14 0.5 ~ 4.0 40 ~ 100 0.10 ~ 0.22 0.5 ~ 7.0 Hardened steel 50 ~ 100 0.07 ~ 0.15 0.5 ~ 4.0 50 ~ 100 0.10 ~ 0.22 0.5 ~ 7.0 CBAPE - Milling tools Order No.宑庋佷䩋 D L1 L d T Inserts Screw Wrench ICBAPE302016100 16 25 100 16 2 ICBAPE302016160 16 35 160 16 2 ICBAPE302020150 20 35 150 20 2 ICBAPE303020100 20 30 100 20 3 APMT1135 ITS2515 ITK08 ICBAPE303020150 20 35 150 20 3 ICBAPE304025100 25 35 100 25 4 ICBAPE304030120 30 40 120 25 4 ICBAPE305032120 32 40 120 32 5 ICBAPE402025150 25 40 150 25 2 ICBAPE402025200 25 70 200 25 2 ICBAPE402030150 30 40 150 25 2 APMT1604 or ITS4023 ITK15 ICBAPE402030200 30 50 200 25 2 APGT1604 ICBAPE403032150 32 45 150 32 3 ICBAPE403032200 32 80 200 32 3 Customize available. IA050

Каталог Carbidex сменные пластины 2020

Каталог Carbidex сменные пластины 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Каталог Winstar фрезерование

Каталог Winstar фрезерование Каталог Winstar монолитный инструмент 2020

Каталог Winstar монолитный инструмент 2020 Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Каталог Winstar сверление

Каталог Winstar сверление