Каталог Tungaloy инструмент для автоматов швейцарского типа - страница 235

Навигация

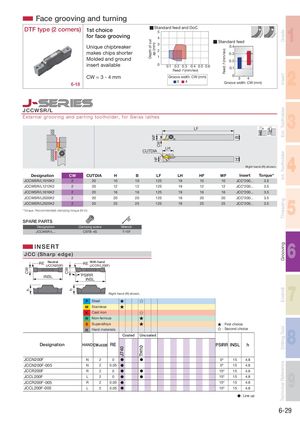

CWh CW h J740 TH10 Depth of cut ap (mm)WFHF CW Feed: f (mm/rev) BH GradeInsertExt. ToolholderInt. ToolholderThreadingGroovingEndmillDrilling ToolTechnical Reference Face grooving and turning DTF type (2 corners) 1st choice Standard feed and DoC5for face grooving4 Standard feed 1 Unique chipbreaker 3 0.4 makes chips shorter 2 0.3 Molded and ground 1 0.2 insert availableCW = 3 - 4 mm6-18 0 0.1 0.2 0.3 0.4 0.5 0.6Feed: f (mm/rev) 0.1Groove width: CW (mm)03434Groove width: CW (mm) 2 JCCWSR/L External grooving and parting toolholder, for Swiss lathes 3 LF CUTDIA LH Right hand (R) shown. 4 Designation CW CUTDIA H B LF LH HF WF Insert Torque* JCCWSR/L1010K2 2 20 10 10 125 19 10 10 JCC*200... 3.5 JCCWSR/L1212K2 2 20 12 12 125 19 12 12 JCC*200... 3.5 JCCWSR/L1616K2 2 20 16 16 125 19 16 16 JCC*200... 3.5 JCCWSR/L2020K2 2 20 20 20 125 19 20 20 JCC*200... 3.5 JCCWSR/L2525K2 2 20*Torque: Recommended clamping torque (N∙m)2525 125 19 25 25 JCC*200... 3.5 5 SPARE PARTS Designation Clamping screw Wrench JCCWSR/L... CSTB-4S T-15F INSERTJCC(Sharpedge) 6 RE Neutral(JCCN200F) RE With hand(JCCR/L200F) INSL PSIRRINSL Right hand (R) shown. 7 P Steel M Stainless K Cast iron N Non-ferrous S Superalloys : First choice H Hard materials Coated Uncoated : Second choice 8 Designation HAND CW±0.025 RE PSIRR INSL h JCCN200F N 2 0 0º 15 4.8 JCCN200F-005 N 2 0.05 0º 15 4.8 JCCR200F R 2 0JCCL200FL20JCCR200F-005R20.05 15º 15 4.815º154.815º154.8 9 JCCL200F-005 L 2 0.05 15º 15 4.8 : Line up 6-29

Общий каталог Tungaloy 2020 - 2021

Общий каталог Tungaloy 2020 - 2021 Каталог Tungaloy глубокое сверление 2

Каталог Tungaloy глубокое сверление 2 Каталог Tungaloy зубофрезерование

Каталог Tungaloy зубофрезерование Брошюра Tungaloy новая продукция

Брошюра Tungaloy новая продукция Каталог Tungaloy глубокое сверление 1

Каталог Tungaloy глубокое сверление 1