Общий каталог Sumitomo 2018 - 2019 - страница 563

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

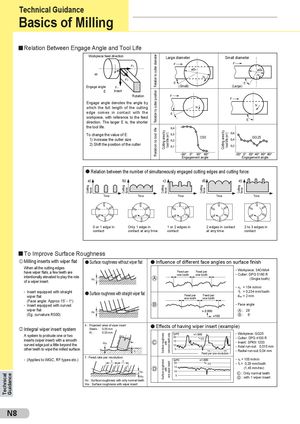

Technical Guidance Cutting force B Cutting force Relation to cutter diameterRelation to cutter positionRelation to tool life Cutting area by tool life (m3)CuttingforceSurface roughnessSurface roughnesswithwithcommon teeth onlyone wiper insert Cutting force Cutting area by tool life (m3) Cutting force Technical Guidance Basics of Milling Relation Between Engage Angle and Tool Life Workpiece feed direction Large diameter Small diameter F2 F F øD N N F3 E E Engage angle F1 (Small) (Large) E Insert Rotation F F Engage angle denotes the angle bywhich the full length of the cutting N N edge comes in contact with the E workpiece, with reference to the feeddirection. The larger E is, the shorter E the tool life. To change the value of E:1) Increase the cutter size C50 GG 25 2) Shift the position of the cutter Engagement angle Engagement angle l Relation between the number of simultaneously engaged cutting edges and cutting force: Time Time Time Time Time 0 or 1 edge in Only 1 edge in 1 or 2 edges in 2 edges in contact 2 to 3 edges in contact contact at any time. contact at any time. contact To Improve Surface Roughness j Milling inserts with wiper flat l Surface roughness without wiper flat l Influence of different face angles on surface finish When all the cutting edgeshave wiper flats, a few teeth areintentionally elevated to play the roleof a wiper insert.HC Feed per Feed per - Workpiece: 34CrMo4one toothone tooth- Cutter: DPG 5160 RA(Single tooth) - vc = 154 m/min - Insert equipped with straightwiper flatl Surface roughness with straight wiper flat(Face angle: Approx 15’ - 1°) ft = 0,234 mm/toothFeed perFeed perone toothone toothdoc = 2 mm - Insert equipped with curved B - Face angle wiper flat(Eg. curvature R500) HF A : 28’B:6’ h : Projected value of wiper insertk Integral wiper insert systemSteels :0,05 mml Effects of having wiper insert (example) Al : 0,03 mmA system to protrude one or twoinserts (wiper insert) with a smoothcurved edge just a little beyond theHW - Workpiece: GG252020- Cutter: DPG 4100 RC15- Insert: SPKN 120310- Axial run-out:0,015 mm other teeth to wipe the milled surface. h 5 - Radial run-out: 0,04 mm Feed per one revolution - (Applies to WGC, RF types etc.) f : Feed rate per revolutionf f - vc = 105 m/min2020-ft =0,29 mm/tooth D 15 (1,45 mm/rev) HC 10 C : Only normal teeth HW 5 D : with 1 wiper insert Hc : Surface roughness with only normal teeth Hw : Surface roughness with wiper insert N8

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части