Общий каталог Sumitomo 2018 - 2019 - страница 34

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

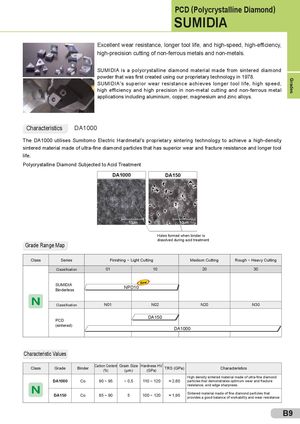

Grades PCD (Polycrystalline Diamond) SUMIDIA Excellent wear resistance, longer tool life, and high-speed, high-efficiency, high-precision cutting of non-ferrous metals and non-metals. SUMIDIA is a polycrystalline diamond material made from sintered diamond powder that was first created using our proprietary technology in 1978. SUMIDIA's superior wear resistance achieves longer tool life, high speed, high efficiency and high precision in non-metal cutting and non-ferrous metal applications including aluminium, copper, magnesium and zinc alloys. Characteristics DA1000 The DA1000 utilises Sumitomo Electric Hardmetal's proprietary sintering technology to achieve a high-density sintered material made of ultra-fine diamond particles that has superior wear and fracture resistance and longer tool life. Polycrystalline Diamond Subjected to Acid Treatment DA1000 DA150 10μm 10μm Holes formed when binder is dissolved during acid treatment Grade Range Map Class Series Finishing ~ Light Cutting Medium Cutting Rough ~ Heavy Cutting Classification 01 10 20 30 SUMIDIABinderless NewNPD10 Classification N01 N02 N20 N30 DA150 PCD (sintered) DA1000 Characteristic Values Class Grade Binder Carbon Content(%)Grain Size(μm)Hardness HV(GPa)TRS (GPa) Characteristics High density sintered material made of ultra-fine diamond DA1000 Co 90 ~ 95 ~ 0,5 110 ~ 120 ≈ 2,60 particles that demonstrates optimum wear and fracture resistance, and edge sharpness. DA150 Co 85 ~ 90 5 100 ~ 120 ≈ 1,95 Sintered material made of fine diamond particles thatprovides a good balance of workability and wear resistance. B9

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части