Общий каталог Sumitomo 2018 - 2019 - страница 33

Навигация

- Pages 3-6_CS6_EN_web

- A 1-20 insert selection EN_web

- B 1-14 grades_EN_web

- C01-17 inserts intro pages_EN_web

- C18-56 negative inserts_EN_web

- C57-86 positive inserts_EN_web

- D 1-46 tool holders_EN_web

- E 1-24 boring bars_EN_web

- F 1-48 grooving_thread tools_EN_web

- G 1-54 milling cutters_EN_web

- H 1-48 insert type endmills_EN_web

- J 1-24 new endmills_EN_web

- J 25-50 endmills_EN_web

- K 1-46 Multi-Drills_EN_web

- K 47-76 Multi-Drills_EN_web

- L 1-28 cbn_pcd grades_EN_web

- M 1-34 cbn_pcd inserts_EN_web

- M 35-56 SHM tools_EN_web

- N1-24 technical guidance_EN_web

- P 1-8 spare parts_neu_EN_web

- P 9-22 index_notes_EN_web

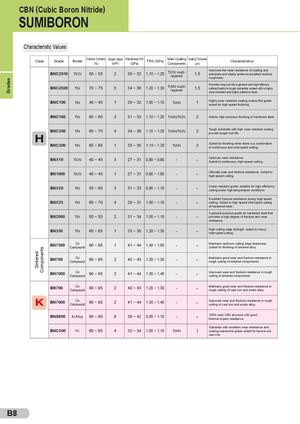

Grades Sintered Components CBN (Cubic Boron Nitride) SUMIBORON Characteristic Values Class Grade Binder Carbon Content(%)Grain Size(μm)Hardness HV(GPa)TRS (GPa)Main Coating Coating ThicknessComponents(µm) Characteristics BNC2010 TiCN 50 ~ 55 2 30 ~ 32 1,10 ~ 1,20 TiCN multi-layered 1,5 Improves the wear resistance of coating andsubstrate and stably achieves excellent surfaceroughness. BNC2020 TiN 70 ~ 75 5 34 ~ 36 1,20 ~ 1,30 TiAlN multi-layered1,5 Provides long tool life in general and high-efficincycutting thanks to tough substrate coated with a highlywear-resistant and highly adhesive layer. BNC100 TiN 40 ~ 45 1 29 ~ 32 1,05 ~ 1,15 TiAlN 1 Highly wear resistant coating makes this gradesuited for high speed finishing. BNC160 TiN 60 ~ 65 3 31 ~ 33 1,10 ~ 1,20 TiAlN/TiCN 2 Stable, high precision finishing of hardened steel. BNC200 TiN 65 ~ 70 4 34 ~ 36 1,15 ~ 1,25 TiAlN/TiCN 2 Tough substrate with high wear resistant coatingprovide longer tool life. BNC300 TiN 60 ~ 65 1 33 ~ 35 1,15 ~ 1,25 TiAlN 2 Suited for finishing when there is a combinationof continuous and interrupted cutting. BNX10 TiCN 40 ~ 45 3 27 ~ 31 0,80 ~ 0,90 ̶ ̶ Optimum wear resistance.Suited to continuous, high-speed cutting. BN1000 TiCN 40 ~ 45 1 27 ~ 31 0,90 ~ 1,00 ̶ ̶ Ultimate wear and fracture resistance. Suited tohigh-speed cutting. BNX20 TiN 55 ~ 60 3 31 ~ 33 0,95 ~ 1,10 ̶ ̶ Crater resistant grade, suitable for high efficiencycutting under high temperature conditions. Excellent fracture resistance during high speed BNX25 TiN 65 ~ 70 4 29 ~ 31 1,00 ~ 1,10 ̶ ̶ cutting. Suited to high speed interrupted cutting of hardened steel. A general purpose grade for hardened steel that BN2000 TiN 50 ~ 55 2 31 ~ 34 1,05 ~ 1,15 ̶ ̶ provides a high degree of fracture and wear resistance. BN350 TiN 60 ~ 65 1 33 ~ 35 1,20 ~ 1,30 ̶ ̶ High cutting edge strength. suited to heavyinterrupted cutting. BN7500 CoCompound 90 ~ 95 1 41 ~ 44 1,40 ~ 1,50 ̶ ̶ Maintains optimum cutting edge sharpness.Suited for finishing of sintered alloy. BN700 CoCompound 90 ~ 95 2 40 ~ 43 1,20 ~ 1,30 ̶ ̶ Maintains good wear and fracture resistance inrough cutting of sintered components. BN7000 CoCompound 90 ~ 95 2 41 ~ 44 1,30 ~ 1,40 ̶ ̶ Improved wear and fracture resistance in roughcutting of sintered components. BN700 CoCompound 90 ~ 95 2 40 ~ 43 1,20 ~ 1,30 ̶ ̶ Maintains good wear and fracture resistance inrough cutting of cast iron and exotic alloy. BN7000 CoCompound 90 ~ 95 2 41 ~ 44 1,30 ~ 1,40 ̶ ̶ Improved wear and fracture resistance in roughcutting of cast iron and exotic alloy. BNS800 Al Alloy 85 ~ 90 8 39 ~ 42 0,95 ~ 1,10 ̶ ̶ 100% solid CBN structure with goodthermal impact resistance. Substrate with excellent wear resistance and BNC500 TiC 60 ~ 65 4 32 ~ 34 1,00 ~ 1,10 TiAlN 2 coating makes this grade suited for hard-to-cut cast iron. B8

Общий каталог Sumitomo 2012

Общий каталог Sumitomo 2012 Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo запасные части

Каталог Sumitomo запасные части