Каталог Stellram токарный инструмент - страница 14

Навигация

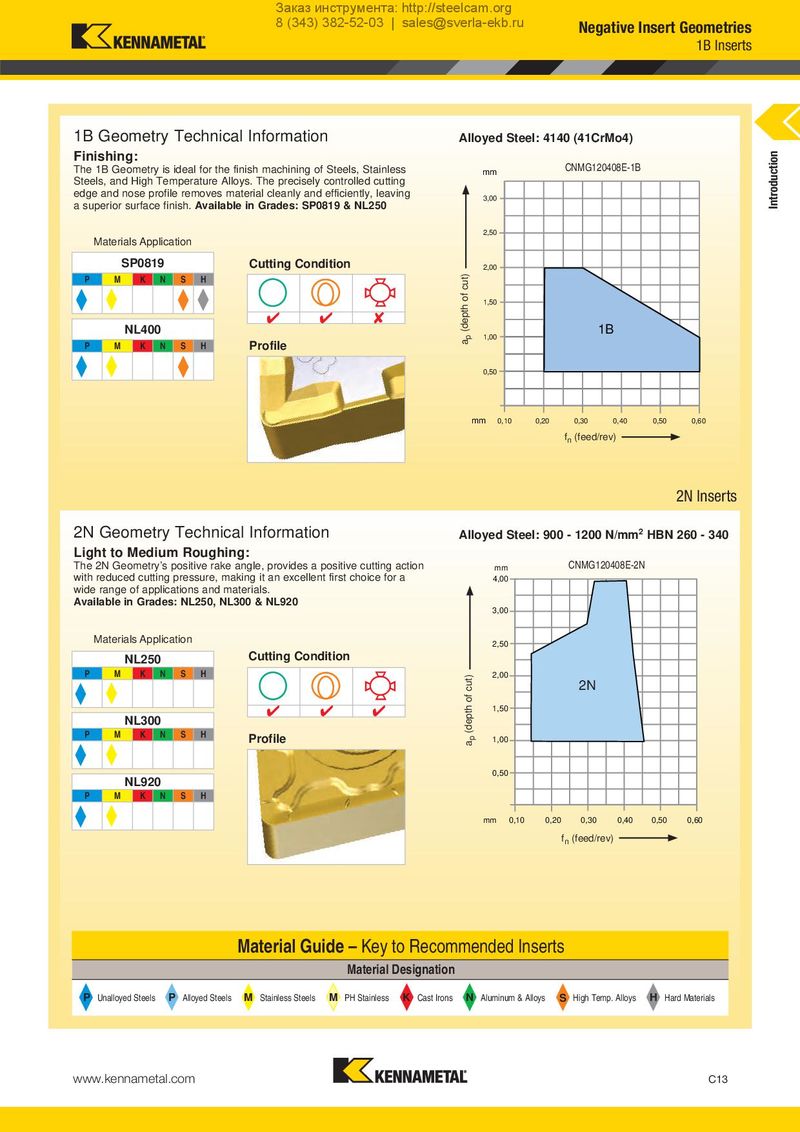

Заказ инструмента: http://steelcam.org 8 (343) 382-52-03 | sales@sverla-ekb.ru Negative Insert Geometries 1B Inserts 1B Geometry Technical Information CNMG12A04l0l8oE-y1Bed SteelA:ll4o1ye4d0S(t4ee1lC: 4r1M40o4(4)1CrMo4) CNMG432A-1B Finishing: Introduction The 1B Geometry is ideal for the finish machining of Steels, Stainless inch mm CNMG120408E-1B Steels, and High Temperature Alloys. The precisely controlled cutting edge and nose profile removes material cleanly and efficiently, leaving 0.118 3,00 a superior surface finish. Available in Grades: SP0819 & NL250 0.100 2,50 Materials Application SP0819 Cutting Condition 0.080 2,00 P M K N S H ap (depth of cut) ap (depth of cut) 0.060 1,50 4 4 8 1B NL400 0.040 1,00 P M K N S H Profile 0.020 0,50 mm 0,10 0,20 0,30 0,40 0,50 0,60 inch 0.004 0.008 fn 0(.f0e1e2d/rev0).016 0.020 0.023 fn (feed /rev) 2N Inserts 2N Geometry Technical Information Alloyed Steel: 900 - 1200 N/mm2 HBN 260 - 340 Light to Medium Roughing: The 2N Geometry’s positive rake angle, provides a positive cutting action inch mm CNMG120408E-2N with reduced cutting pressure, making it an excellent first choice for a 0.157 4,00 wide range of applications and materials. Available in Grades: NL250, NL300 & NL920 0.118 3,00 Materials Application 0.100 2,50 NL250 Cutting Condition P M K N S H 0.080 2,00 ap (depth of cut) 2N 4 4 4 0.060 1,50 NL300 P M K N S H Profile ap (depth of cut) 0.040 1,00 0.020 0,50 NL920 P M K N S H mm 0,10 0,20 0,30 0,40 0,50 0,60 inch 0.004 0.008fn (fe0e.0d1/2rev) 0.016 0.020 0.023 fn (feed/rev) Material Guide – Key to Recommended Inserts Material Designation PP Unalloyed Steels PP Alloyed Steels MM Stainless Steels MM PH Stainless KK Cast Irons NN Aluminum & Alloys SS High Temp. Alloys HH Hard Materials www.kennametal.com C13

Каталог Stellram материалы и сплавы

Каталог Stellram материалы и сплавы Каталог Stellram твердосплавные цельные фрезы

Каталог Stellram твердосплавные цельные фрезы Каталог Stellram фрез со сменными пластинами

Каталог Stellram фрез со сменными пластинами Каталог Stellram высокопроизводительные фрезерные системы

Каталог Stellram высокопроизводительные фрезерные системы Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами

Каталог Stellram системы со сменными пластинами для фрезерования с высокими подачами