Общий каталог SGS 2018 - страница 68

Навигация

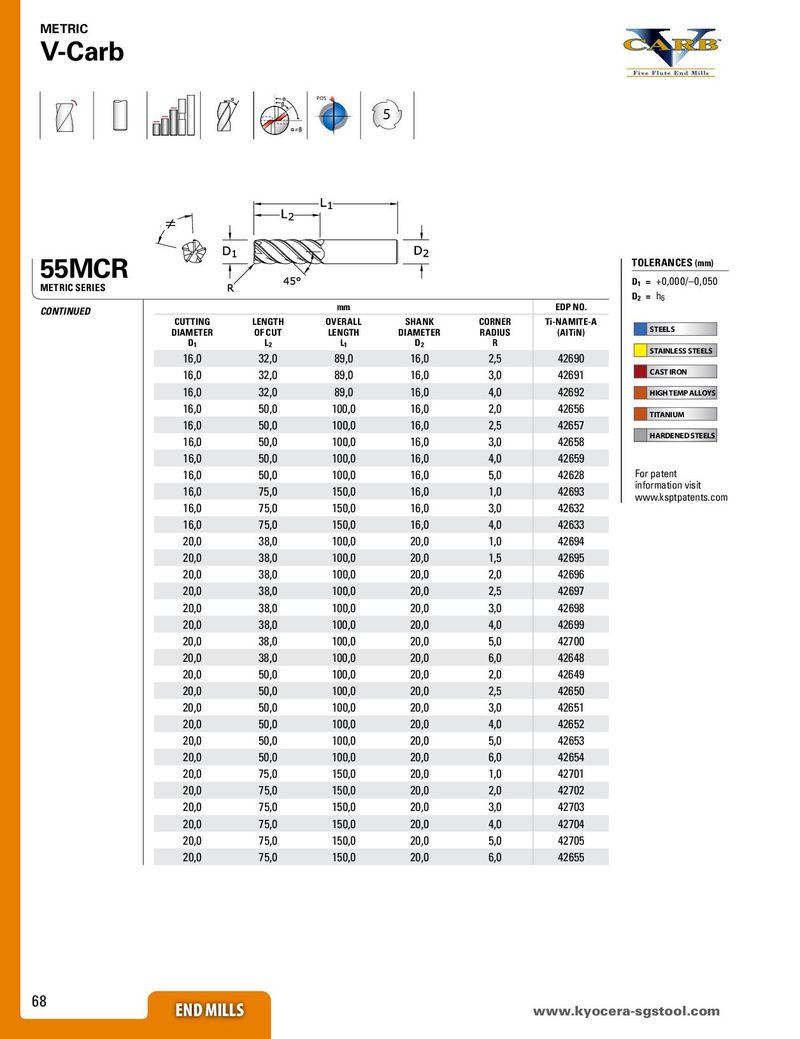

METRIC V-Carb POS 5 ≠ 55MCR TOLERANCES (mm) METRIC SERIES D1 = +0,000/–0,050 D2 = h6 CONTINUED mm EDP NO. CUTTING LENGTH OVERALL SHANK CORNER Ti-NAMITE-A DIAMETER OF CUT LENGTH DIAMETER RADIUS (AlTiN) STEELS D1 L2 L1 D2 R 16,0 32,0 89,0 16,0 2,5 42690 STAINLESS STEELS 16,0 32,0 89,0 16,0 3,0 42691 CAST IRON 16,0 32,0 89,0 16,0 4,0 42692 HIGH TEMP ALLOYS 16,0 50,0 100,0 16,0 2,0 42656 TITANIUM 16,0 50,0 100,0 16,0 2,5 42657 16,0 50,0 100,0 16,0 3,0 42658 HARDENED STEELS 16,0 50,0 100,0 16,0 4,0 42659 16,0 50,0 100,0 16,0 5,0 42628 For patent 16,0 75,0 150,0 16,0 1,0 42693 information visit www.ksptpatents.com 16,0 75,0 150,0 16,0 3,0 42632 16,0 75,0 150,0 16,0 4,0 42633 20,0 38,0 100,0 20,0 1,0 42694 20,0 38,0 100,0 20,0 1,5 42695 20,0 38,0 100,0 20,0 2,0 42696 20,0 38,0 100,0 20,0 2,5 42697 20,0 38,0 100,0 20,0 3,0 42698 20,0 38,0 100,0 20,0 4,0 42699 20,0 38,0 100,0 20,0 5,0 42700 20,0 38,0 100,0 20,0 6,0 42648 20,0 50,0 100,0 20,0 2,0 42649 20,0 50,0 100,0 20,0 2,5 42650 20,0 50,0 100,0 20,0 3,0 42651 20,0 50,0 100,0 20,0 4,0 42652 20,0 50,0 100,0 20,0 5,0 42653 20,0 50,0 100,0 20,0 6,0 42654 20,0 75,0 150,0 20,0 1,0 42701 20,0 75,0 150,0 20,0 2,0 42702 20,0 75,0 150,0 20,0 3,0 42703 20,0 75,0 150,0 20,0 4,0 42704 20,0 75,0 150,0 20,0 5,0 42705 20,0 75,0 150,0 20,0 6,0 42655 68 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском