Общий каталог SGS 2018 - страница 67

Навигация

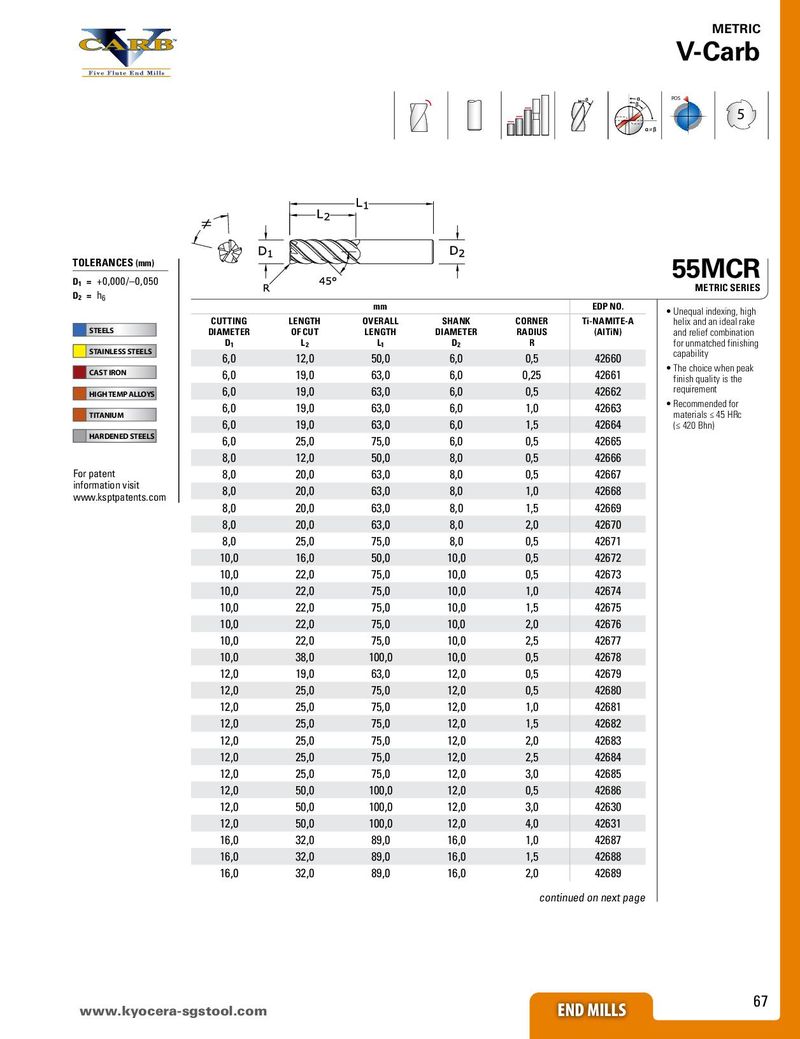

METRIC V-Carb POS 5 ≠ TOLERANCES (mm) 55MCR D1 = +0,000/–0,050 METRIC SERIES D2 = h6 mm EDP NO. • Unequal indexing, high CUTTING LENGTH OVERALL SHANK CORNER Ti-NAMITE-A helix and an ideal rake STEELS DIAMETER OF CUT LENGTH DIAMETER RADIUS (AlTiN) and relief combination D1 L2 L1 D2 R for unmatched finishing STAINLESS STEELS 6,0 12,0 50,0 6,0 0,5 42660 capability CAST IRON 6,0 19,0 63,0 6,0 0,25 42661 • The choice when peak finish quality is the HIGH TEMP ALLOYS 6,0 19,0 63,0 6,0 0,5 42662 requirement 6,0 19,0 63,0 6,0 1,0 42663 • Recommended for TITANIUM materials ≤ 45 HRc 6,0 19,0 63,0 6,0 1,5 42664 (≤ 420 Bhn) HARDENED STEELS 6,0 25,0 75,0 6,0 0,5 42665 8,0 12,0 50,0 8,0 0,5 42666 For patent 8,0 20,0 63,0 8,0 0,5 42667 information visit 8,0 20,0 63,0 8,0 1,0 42668 www.ksptpatents.com 8,0 20,0 63,0 8,0 1,5 42669 8,0 20,0 63,0 8,0 2,0 42670 8,0 25,0 75,0 8,0 0,5 42671 10,0 16,0 50,0 10,0 0,5 42672 10,0 22,0 75,0 10,0 0,5 42673 10,0 22,0 75,0 10,0 1,0 42674 10,0 22,0 75,0 10,0 1,5 42675 10,0 22,0 75,0 10,0 2,0 42676 10,0 22,0 75,0 10,0 2,5 42677 10,0 38,0 100,0 10,0 0,5 42678 12,0 19,0 63,0 12,0 0,5 42679 12,0 25,0 75,0 12,0 0,5 42680 12,0 25,0 75,0 12,0 1,0 42681 12,0 25,0 75,0 12,0 1,5 42682 12,0 25,0 75,0 12,0 2,0 42683 12,0 25,0 75,0 12,0 2,5 42684 12,0 25,0 75,0 12,0 3,0 42685 12,0 50,0 100,0 12,0 0,5 42686 12,0 50,0 100,0 12,0 3,0 42630 12,0 50,0 100,0 12,0 4,0 42631 16,0 32,0 89,0 16,0 1,0 42687 16,0 32,0 89,0 16,0 1,5 42688 16,0 32,0 89,0 16,0 2,0 42689 continued on next page www.kyocerEaN-DsgMstILoLoSl.com END MILLS 67

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском