Общий каталог SGS 2018 - страница 40

Навигация

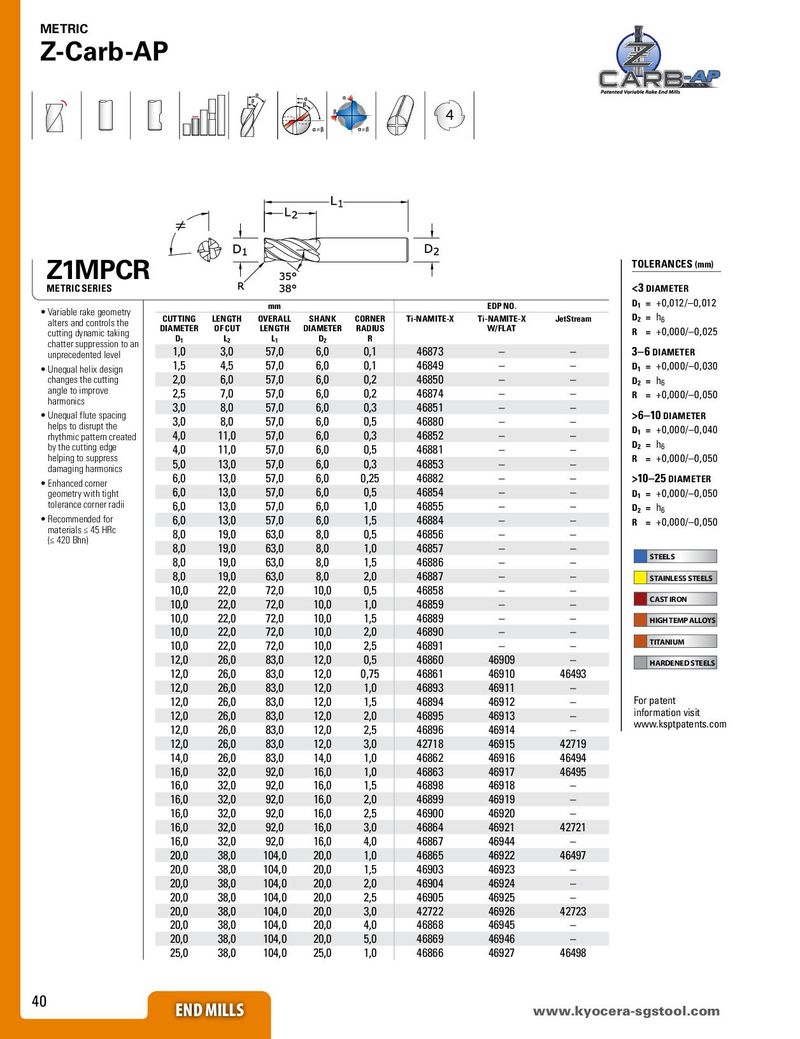

METRIC Z-Carb-AP 4 ≠ ≠ Z1MPCR TOLERANCES (mm) METRIC SERIES <3 DIAMETER • Variable rake geometry mm EDP NO. D1 = +0,012/–0,012 alters and controls the CUTTING LENGTH OVERALL SHANK CORNER Ti-NAMITE-X Ti-NAMITE-X JetStream D2 = h6 cutting dynamic taking DIAMETER OF CUT LENGTH DIAMETER RADIUS W/FLAT R = +0,000/–0,025 chatter suppression to an D1 L2 L1 D2 R unprecedented level 1,0 3,0 57,0 6,0 0,1 46873 – – 3–6 DIAMETER • Unequal helix design 1,5 4,5 57,0 6,0 0,1 46849 – – D1 = +0,000/–0,030 changes the cutting 2,0 6,0 57,0 6,0 0,2 46850 – – D2 = h6 angle to improve 2,5 7,0 57,0 6,0 0,2 46874 – – R = +0,000/–0,050 harmonics 3,0 8,0 57,0 6,0 0,3 46851 – – • Unequal flute spacing 3,0 8,0 57,0 6,0 0,5 46880 – – >6–10 DIAMETER helps to disrupt the 4,0 11,0 57,0 6,0 0,3 46852 – – D1 = +0,000/–0,040 rhythmic pattern created D2 = h6 by the cutting edge 4,0 11,0 57,0 6,0 0,5 46881 – – helping to suppress 5,0 13,0 57,0 6,0 0,3 46853 – – R = +0,000/–0,050 damaging harmonics 6,0 13,0 57,0 6,0 0,25 46882 – – >10–25 DIAMETER • Enhanced corner 6,0 13,0 57,0 6,0 0,5 46854 – – geometry with tight D1 = +0,000/–0,050 tolerance corner radii 6,0 13,0 57,0 6,0 1,0 46855 – – D2 = h6 • Recommended for 6,0 13,0 57,0 6,0 1,5 46884 – – R = +0,000/–0,050 materials ≤ 45 HRc 8,0 19,0 63,0 8,0 0,5 46856 – – (≤ 420 Bhn) 8,0 19,0 63,0 8,0 1,0 46857 – – 8,0 19,0 63,0 8,0 1,5 46886 – – STEELS 8,0 19,0 63,0 8,0 2,0 46887 – – STAINLESS STEELS 10,0 22,0 72,0 10,0 0,5 46858 – – 10,0 22,0 72,0 10,0 1,0 46859 – – CAST IRON 10,0 22,0 72,0 10,0 1,5 46889 – – HIGH TEMP ALLOYS 10,0 22,0 72,0 10,0 2,0 46890 – – 10,0 22,0 72,0 10,0 2,5 46891 – – TITANIUM 12,0 26,0 83,0 12,0 0,5 46860 46909 – HARDENED STEELS 12,0 26,0 83,0 12,0 0,75 46861 46910 46493 12,0 26,0 83,0 12,0 1,0 46893 46911 – 12,0 26,0 83,0 12,0 1,5 46894 46912 – For patent 12,0 26,0 83,0 12,0 2,0 46895 46913 – information visit 12,0 26,0 83,0 12,0 2,5 46896 46914 – www.ksptpatents.com 12,0 26,0 83,0 12,0 3,0 42718 46915 42719 14,0 26,0 83,0 14,0 1,0 46862 46916 46494 16,0 32,0 92,0 16,0 1,0 46863 46917 46495 16,0 32,0 92,0 16,0 1,5 46898 46918 – 16,0 32,0 92,0 16,0 2,0 46899 46919 – 16,0 32,0 92,0 16,0 2,5 46900 46920 – 16,0 32,0 92,0 16,0 3,0 46864 46921 42721 16,0 32,0 92,0 16,0 4,0 46867 46944 – 20,0 38,0 104,0 20,0 1,0 46865 46922 46497 20,0 38,0 104,0 20,0 1,5 46903 46923 – 20,0 38,0 104,0 20,0 2,0 46904 46924 – 20,0 38,0 104,0 20,0 2,5 46905 46925 – 20,0 38,0 104,0 20,0 3,0 42722 46926 42723 20,0 38,0 104,0 20,0 4,0 46868 46945 – 20,0 38,0 104,0 20,0 5,0 46869 46946 – 25,0 38,0 104,0 25,0 1,0 46866 46927 46498 40 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском