Общий каталог SGS 2018 - страница 26

Навигация

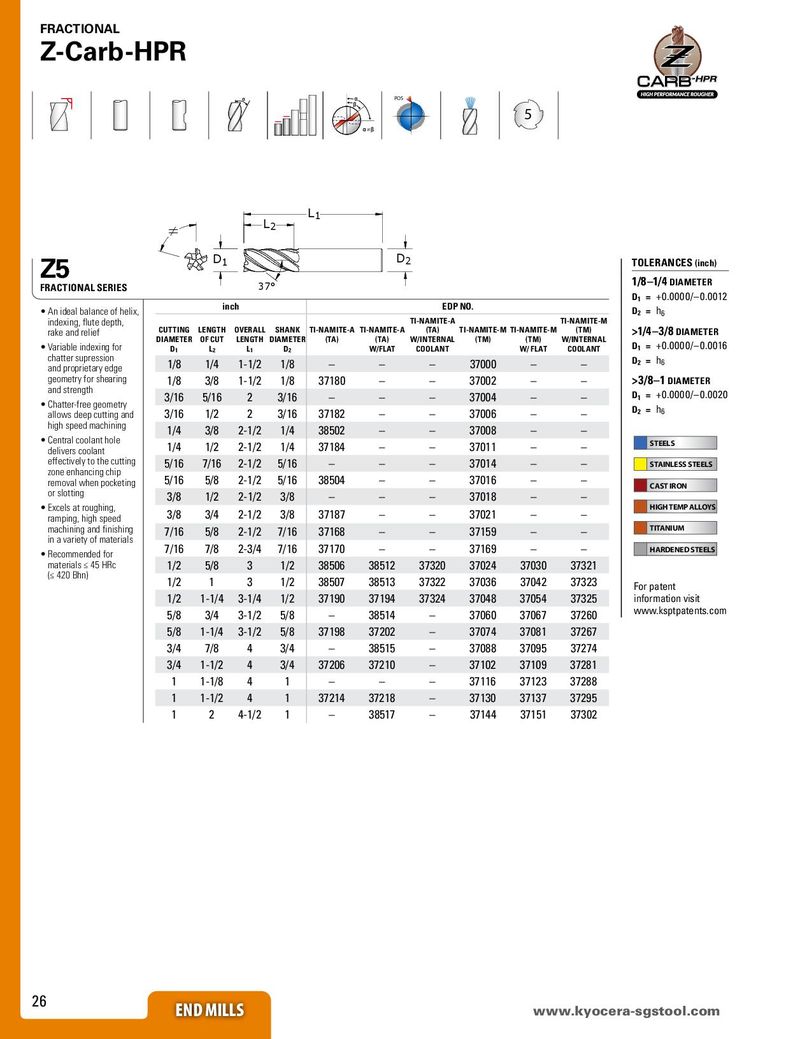

FRACTIONAL Z-Carb-HPR POS 5 ≠ L2 L1 Z5 D1 D2 TOLERANCES (inch) FRACTIONAL SERIES 37° 1/8–1/4 DIAMETER D1 = +0.0000/–0.0012 • An ideal balance of helix, inch EDP NO. D2 = h6 indexing, flute depth, TI-NAMITE-A TI-NAMITE-M rake and relief CUTTING LENGTH OVERALL SHANK TI-NAMITE-A TI-NAMITE-A (TA) TI-NAMITE-M TI-NAMITE-M (TM) >1/4–3/8 DIAMETER • Variable indexing for DIAMETER OF CUT LENGTH DIAMETER (TA) (TA) W/INTERNAL (TM) (TM) W/INTERNAL D1 = +0.0000/–0.0016 D1 L2 L1 D2 W/FLAT COOLANT W/ FLAT COOLANT chatter supression 1/8 1/4 1-1/2 1/8 – – – 37000 – – D2 = h6 and proprietary edge geometry for shearing 1/8 3/8 1-1/2 1/8 37180 – – 37002 – – >3/8–1 DIAMETER and strength 3/16 5/16 2 3/16 – – – 37004 – – D1 = +0.0000/–0.0020 • Chatter-free geometry 3/16 1/2 2 3/16 37182 – – 37006 – – D2 = h6 allows deep cutting and high speed machining 1/4 3/8 2-1/2 1/4 38502 – – 37008 – – • Central coolant hole 1/4 1/2 2-1/2 1/4 37184 – – 37011 – – STEELS delivers coolant effectively to the cutting 5/16 7/16 2-1/2 5/16 – – – 37014 – – STAINLESS STEELS zone enhancing chip 5/16 5/8 2-1/2 5/16 38504 – – 37016 – – removal when pocketing CAST IRON or slotting 3/8 1/2 2-1/2 3/8 – – – 37018 – – • Excels at roughing, 3/8 3/4 2-1/2 3/8 37187 – – 37021 – – HIGH TEMP ALLOYS ramping, high speed machining and finishing 7/16 5/8 2-1/2 7/16 37168 – – 37159 – – TITANIUM in a variety of materials 7/16 7/8 2-3/4 7/16 37170 – – 37169 – – • Recommended for HARDENED STEELS materials ≤ 45 HRc 1/2 5/8 3 1/2 38506 38512 37320 37024 37030 37321 (≤ 420 Bhn) 1/2 1 3 1/2 38507 38513 37322 37036 37042 37323 For patent 1/2 1-1/4 3-1/4 1/2 37190 37194 37324 37048 37054 37325 information visit 5/8 3/4 3-1/2 5/8 – 38514 – 37060 37067 37260 www.ksptpatents.com 5/8 1-1/4 3-1/2 5/8 37198 37202 – 37074 37081 37267 3/4 7/8 4 3/4 – 38515 – 37088 37095 37274 3/4 1-1/2 4 3/4 37206 37210 – 37102 37109 37281 1 1-1/8 4 1 – – – 37116 37123 37288 1 1-1/2 4 1 37214 37218 – 37130 37137 37295 1 2 4-1/2 1 – 38517 – 37144 37151 37302 26 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском