Общий каталог SGS 2018 - страница 27

Навигация

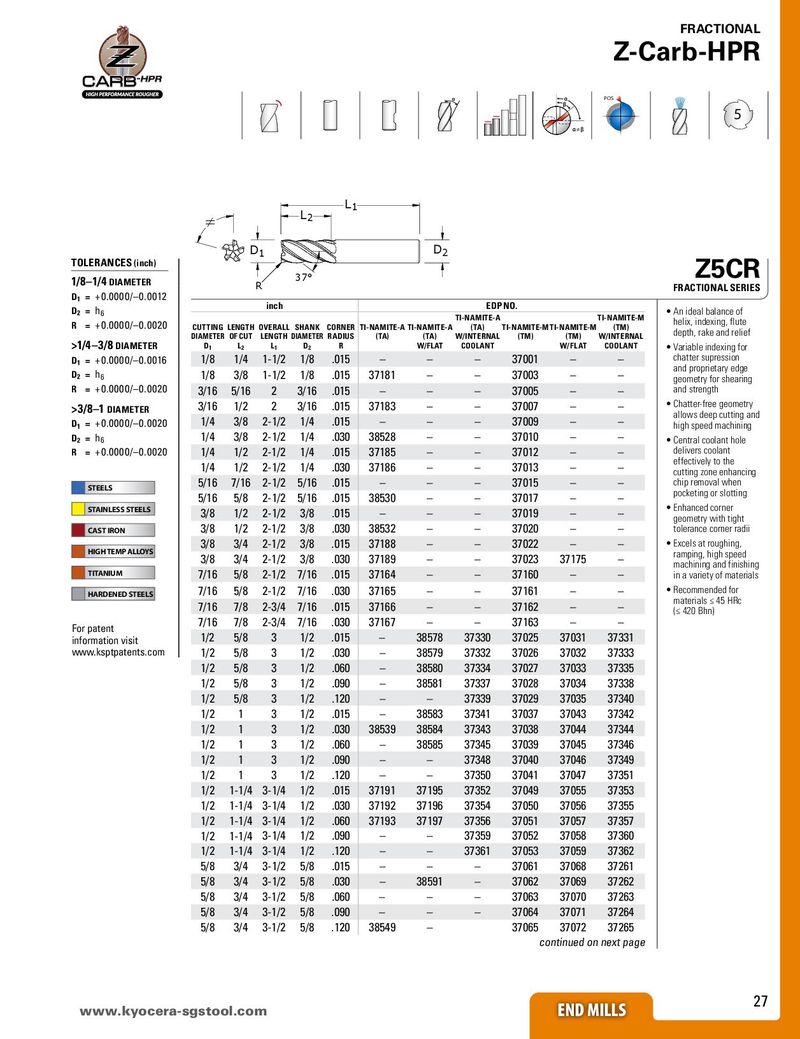

FRACTIONAL Z-Carb-HPR POS 5 ≠ L2 L1 D1 D2 TOLERANCES (inch) Z5CR 1/8–1/4 DIAMETER R 37° D1 = +0.0000/–0.0012 FRACTIONAL SERIES D2 = h6 inch EDP NO. • An ideal balance of R = +0.0000/–0.0020 TI-NAMITE-A TI-NAMITE-M helix, indexing, flute CUTTING LENGTH OVERALL SHANK CORNER TI-NAMITE-A TI-NAMITE-A (TA) TI-NAMITE-M TI-NAMITE-M (TM) depth, rake and relief >1/4–3/8 DIAMETER DIAMETER OF CUT LENGTH DIAMETER RADIUS (TA) (TA) W/INTERNAL (TM) (TM) W/INTERNAL D1 L2 L1 D2 R W/FLAT COOLANT W/ FLAT COOLANT • Variable indexing for D1 = +0.0000/–0.0016 1/8 1/4 1-1/2 1/8 .015 – – – 37001 – – chatter supression D2 = h6 1/8 3/8 1-1/2 1/8 .015 37181 – – 37003 – – and proprietary edge geometry for shearing R = +0.0000/–0.0020 3/16 5/16 2 3/16 .015 – – – 37005 – – and strength >3/8–1 DIAMETER 3/16 1/2 2 3/16 .015 37183 – – 37007 – – • Chatter-free geometry D1 = +0.0000/–0.0020 1/4 3/8 2-1/2 1/4 .015 – – – 37009 – – allows deep cutting and high speed machining D2 = h6 1/4 3/8 2-1/2 1/4 .030 38528 – – 37010 – – • Central coolant hole R = +0.0000/–0.0020 1/4 1/2 2-1/2 1/4 .015 37185 – – 37012 – – delivers coolant 1/4 1/2 2-1/2 1/4 .030 37186 – – 37013 – – effectively to the cutting zone enhancing STEELS 5/16 7/16 2-1/2 5/16 .015 – – – 37015 – – chip removal when 5/16 5/8 2-1/2 5/16 .015 38530 – – 37017 – – pocketing or slotting STAINLESS STEELS 3/8 1/2 2-1/2 3/8 .015 – – – 37019 – – • Enhanced corner geometry with tight CAST IRON 3/8 1/2 2-1/2 3/8 .030 38532 – – 37020 – – tolerance corner radii 3/8 3/4 2-1/2 3/8 .015 37188 – – 37022 – – • Excels at roughing, HIGH TEMP ALLOYS 3/8 3/4 2-1/2 3/8 .030 37189 – – 37023 37175 – ramping, high speed machining and finishing TITANIUM 7/16 5/8 2-1/2 7/16 .015 37164 – – 37160 – – in a variety of materials HARDENED STEELS 7/16 5/8 2-1/2 7/16 .030 37165 – – 37161 – – • Recommended for 7/16 7/8 2-3/4 7/16 .015 37166 – – 37162 – – materials ≤ 45 HRc (≤ 420 Bhn) For patent 7/16 7/8 2-3/4 7/16 .030 37167 – – 37163 – – information visit 1/2 5/8 3 1/2 .015 – 38578 37330 37025 37031 37331 www.ksptpatents.com 1/2 5/8 3 1/2 .030 – 38579 37332 37026 37032 37333 1/2 5/8 3 1/2 .060 – 38580 37334 37027 37033 37335 1/2 5/8 3 1/2 .090 – 38581 37337 37028 37034 37338 1/2 5/8 3 1/2 .120 – – 37339 37029 37035 37340 1/2 1 3 1/2 .015 – 38583 37341 37037 37043 37342 1/2 1 3 1/2 .030 38539 38584 37343 37038 37044 37344 1/2 1 3 1/2 .060 – 38585 37345 37039 37045 37346 1/2 1 3 1/2 .090 – – 37348 37040 37046 37349 1/2 1 3 1/2 .120 – – 37350 37041 37047 37351 1/2 1-1/4 3-1/4 1/2 .015 37191 37195 37352 37049 37055 37353 1/2 1-1/4 3-1/4 1/2 .030 37192 37196 37354 37050 37056 37355 1/2 1-1/4 3-1/4 1/2 .060 37193 37197 37356 37051 37057 37357 1/2 1-1/4 3-1/4 1/2 .090 – – 37359 37052 37058 37360 1/2 1-1/4 3-1/4 1/2 .120 – – 37361 37053 37059 37362 5/8 3/4 3-1/2 5/8 .015 – – – 37061 37068 37261 5/8 3/4 3-1/2 5/8 .030 – 38591 – 37062 37069 37262 5/8 3/4 3-1/2 5/8 .060 – – – 37063 37070 37263 5/8 3/4 3-1/2 5/8 .090 – – – 37064 37071 37264 5/8 3/4 3-1/2 5/8 .120 38549 – 37065 37072 37265 continued on next page www.kyocerEaN-DsgMstILoLoSl.com END MILLS 27

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском