Общий каталог SGS 2018 - страница 225

Навигация

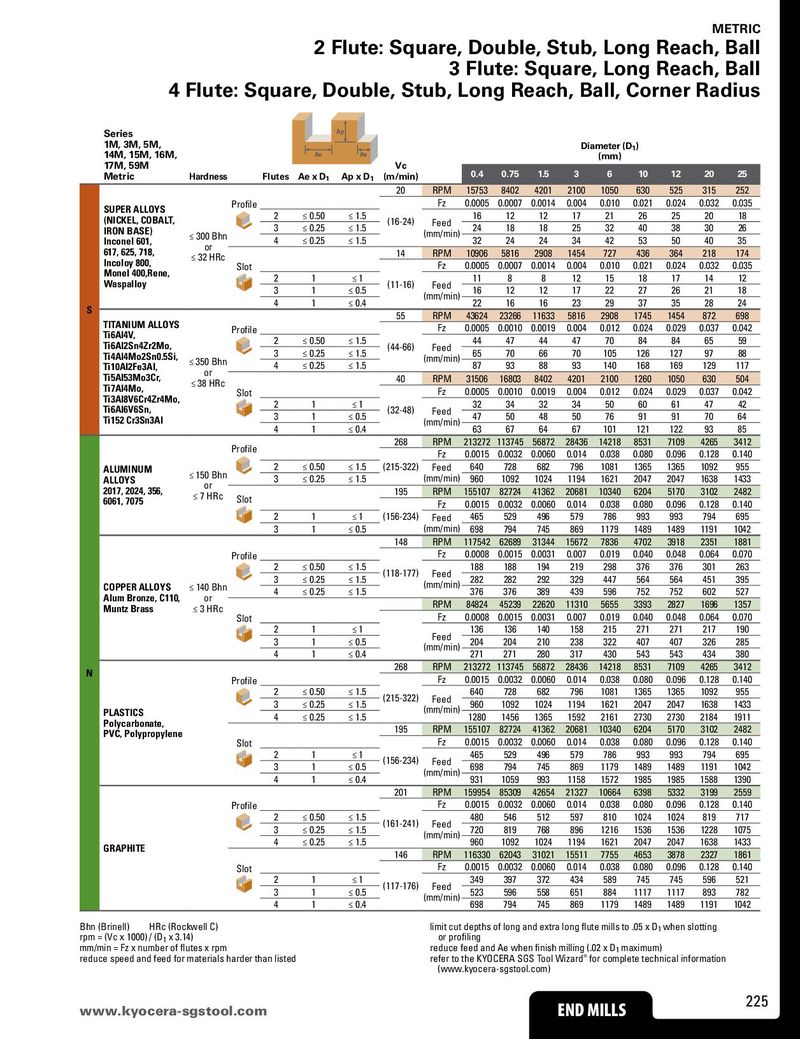

METRIC 2 Flute: Square, Double, Stub, Long Reach, Ball 3 Flute: Square, Long Reach, Ball 4 Flute: Square, Double, Stub, Long Reach, Ball, Corner Radius Series Ap 1M, 3M, 5M, Diameter (D1) 14M, 15M, 16M, Ae Ae (mm) 17M, 59M Vc 0.4 0.75 1.5 3 6 10 12 20 25 Metric Hardness Flutes Ae x D1 Ap x D1 (m/min) 20 RPM 15753 8402 4201 2100 1050 630 525 315 252 SUPER ALLOYS Profile Fz 0.0005 0.0007 0.0014 0.004 0.010 0.021 0.024 0.032 0.035 (NICKEL, COBALT, 2 ≤ 0.50 ≤ 1.5 (16-24) Feed 16 12 12 17 21 26 25 20 18 IRON BASE) ≤ 300 Bhn 3 ≤ 0.25 ≤ 1.5 (mm/min) 24 18 18 25 32 40 38 30 26 Inconel 601, or 4 ≤ 0.25 ≤ 1.5 32 24 24 34 42 53 50 40 35 617, 625, 718, ≤ 32 HRc 14 RPM 10906 5816 2908 1454 727 436 364 218 174 Incoloy 800, Slot Fz 0.0005 0.0007 0.0014 0.004 0.010 0.021 0.024 0.032 0.035 Monel 400,Rene, 2 1 ≤1 11 8 8 12 15 18 17 14 12 Waspalloy 3 1 ≤ 0.5 (11-16) Feed 16 12 12 17 22 27 26 21 18 4 1 ≤ 0.4 (mm/min) 22 16 16 23 29 37 35 28 24 S 55 RPM 43624 23266 11633 5816 2908 1745 1454 872 698 TITANIUM ALLOYS Profile Fz 0.0005 0.0010 0.0019 0.004 0.012 0.024 0.029 0.037 0.042 Ti6Al4V, 2 ≤ 0.50 ≤ 1.5 44 47 44 47 70 84 84 65 59 Ti6Al2Sn4Zr2Mo, 3 ≤ 0.25 ≤ 1.5 (44-66) Feed 65 70 66 70 105 126 127 97 88 Ti4Al4Mo2Sn0.5Si, ≤ 350 Bhn (mm/min) Ti10Al2Fe3Al, or 4 ≤ 0.25 ≤ 1.5 87 93 88 93 140 168 169 129 117 Ti5Al53Mo3Cr, ≤ 38 HRc 40 RPM 31506 16803 8402 4201 2100 1260 1050 630 504 Ti7Al4Mo, Slot Fz 0.0005 0.0010 0.0019 0.004 0.012 0.024 0.029 0.037 0.042 Ti3Al8V6Cr4Zr4Mo, 2 1 ≤1 32 34 32 34 50 60 61 47 42 Ti6Al6V6Sn, 3 1 ≤ 0.5 (32-48) Feed 47 50 48 50 76 91 91 70 64 Ti152 Cr3Sn3Al 4 1 ≤ 0.4 (mm/min) 63 67 64 67 101 121 122 93 85 Profile 268 RPM 213272 113745 56872 28436 14218 8531 7109 4265 3412 Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 ALUMINUM ≤ 150 Bhn 2 ≤ 0.50 ≤ 1.5 (215-322) Feed 640 728 682 796 1081 1365 1365 1092 955 ALLOYS or 3 ≤ 0.25 ≤ 1.5 (mm/min) 960 1092 1024 1194 1621 2047 2047 1638 1433 2017, 2024, 356, ≤ 7 HRc Slot 195 RPM 155107 82724 41362 20681 10340 6204 5170 3102 2482 6061, 7075 Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 2 1 ≤1 (156-234) Feed 465 529 496 579 786 993 993 794 695 3 1 ≤ 0.5 (mm/min) 698 794 745 869 1179 1489 1489 1191 1042 148 RPM 117542 62689 31344 15672 7836 4702 3918 2351 1881 Profile Fz 0.0008 0.0015 0.0031 0.007 0.019 0.040 0.048 0.064 0.070 2 ≤ 0.50 ≤ 1.5 (118-177) Feed 188 188 194 219 298 376 376 301 263 COPPER ALLOYS ≤ 140 Bhn 3 ≤ 0.25 ≤ 1.5 (mm/min) 282 282 292 329 447 564 564 451 395 Alum Bronze, C110, or 4 ≤ 0.25 ≤ 1.5 376 376 389 439 596 752 752 602 527 Muntz Brass ≤ 3 HRc RPM 84824 45239 22620 11310 5655 3393 2827 1696 1357 Slot Fz 0.0008 0.0015 0.0031 0.007 0.019 0.040 0.048 0.064 0.070 2 1 ≤1 Feed 136 136 140 158 215 271 271 217 190 3 1 ≤ 0.5 (mm/min) 204 204 210 238 322 407 407 326 285 4 1 ≤ 0.4 271 271 280 317 430 543 543 434 380 N 268 RPM 213272 113745 56872 28436 14218 8531 7109 4265 3412 Profile Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 2 ≤ 0.50 ≤ 1.5 (215-322) Feed 640 728 682 796 1081 1365 1365 1092 955 PLASTICS 3 ≤ 0.25 ≤ 1.5 (mm/min) 960 1092 1024 1194 1621 2047 2047 1638 1433 Polycarbonate, 4 ≤ 0.25 ≤ 1.5 1280 1456 1365 1592 2161 2730 2730 2184 1911 PVC, Polypropylene 195 RPM 155107 82724 41362 20681 10340 6204 5170 3102 2482 Slot Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 2 1 ≤1 (156-234) Feed 465 529 496 579 786 993 993 794 695 3 1 ≤ 0.5 (mm/min) 698 794 745 869 1179 1489 1489 1191 1042 4 1 ≤ 0.4 931 1059 993 1158 1572 1985 1985 1588 1390 201 RPM 159954 85309 42654 21327 10664 6398 5332 3199 2559 Profile Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 2 ≤ 0.50 ≤ 1.5 (161-241) Feed 480 546 512 597 810 1024 1024 819 717 3 ≤ 0.25 ≤ 1.5 (mm/min) 720 819 768 896 1216 1536 1536 1228 1075 GRAPHITE 4 ≤ 0.25 ≤ 1.5 960 1092 1024 1194 1621 2047 2047 1638 1433 146 RPM 116330 62043 31021 15511 7755 4653 3878 2327 1861 Slot Fz 0.0015 0.0032 0.0060 0.014 0.038 0.080 0.096 0.128 0.140 2 1 ≤1 (117-176) Feed 349 397 372 434 589 745 745 596 521 3 1 ≤ 0.5 (mm/min) 523 596 558 651 884 1117 1117 893 782 4 1 ≤ 0.4 698 794 745 869 1179 1489 1489 1191 1042 Bhn (Brinell) HRc (Rockwell C) limit cut depths of long and extra long flute mills to .05 x D1 when slotting rpm = (Vc x 1000) / (D1 x 3.14) or profiling mm/min = Fz x number of flutes x rpm reduce feed and Ae when finish milling (.02 x D1 maximum) reduce speed and feed for materials harder than listed refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 225

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском