Общий каталог SGS 2018 - страница 107

Навигация

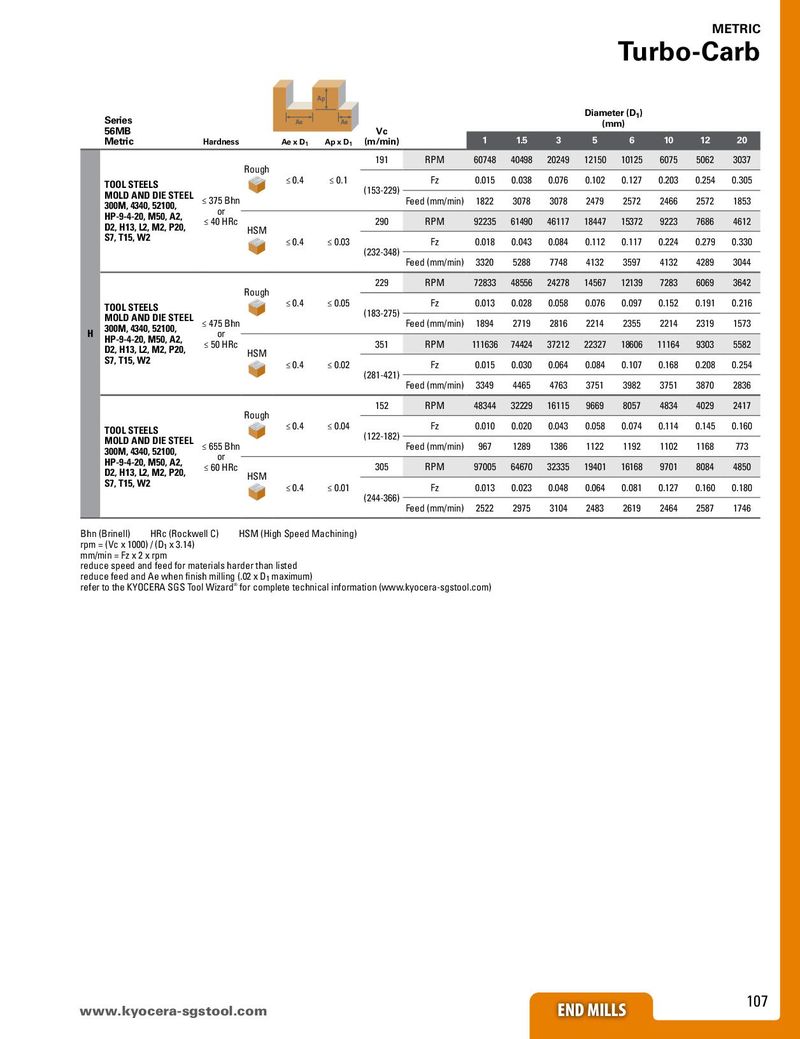

METRIC Turbo-Carb Ap Series Diameter (D1) Ae Ae (mm) 56MB Vc Metric Hardness Ae x D1 Ap x D1 (m/min) 1 1.5 3 5 6 10 12 20 191 RPM 60748 40498 20249 12150 10125 6075 5062 3037 Rough TOOL STEELS ≤ 0.4 ≤ 0.1 Fz 0.015 0.038 0.076 0.102 0.127 0.203 0.254 0.305 MOLD AND DIE STEEL (153-229) 300M, 4340, 52100, ≤ 375 Bhn Feed (mm/min) 1822 3078 3078 2479 2572 2466 2572 1853 HP-9-4-20, M50, A2, or D2, H13, L2, M2, P20, ≤ 40 HRc 290 RPM 92235 61490 46117 18447 15372 9223 7686 4612 S7, T15, W2 HSM ≤ 0.4 ≤ 0.03 Fz 0.018 0.043 0.084 0.112 0.117 0.224 0.279 0.330 (232-348) Feed (mm/min) 3320 5288 7748 4132 3597 4132 4289 3044 229 RPM 72833 48556 24278 14567 12139 7283 6069 3642 Rough TOOL STEELS ≤ 0.4 ≤ 0.05 Fz 0.013 0.028 0.058 0.076 0.097 0.152 0.191 0.216 MOLD AND DIE STEEL (183-275) 300M, 4340, 52100, ≤ 475 Bhn Feed (mm/min) 1894 2719 2816 2214 2355 2214 2319 1573 H HP-9-4-20, M50, A2, or D2, H13, L2, M2, P20, ≤ 50 HRc 351 RPM 111636 74424 37212 22327 18606 11164 9303 5582 S7, T15, W2 HSM ≤ 0.4 ≤ 0.02 Fz 0.015 0.030 0.064 0.084 0.107 0.168 0.208 0.254 (281-421) Feed (mm/min) 3349 4465 4763 3751 3982 3751 3870 2836 152 RPM 48344 32229 16115 9669 8057 4834 4029 2417 Rough TOOL STEELS ≤ 0.4 ≤ 0.04 Fz 0.010 0.020 0.043 0.058 0.074 0.114 0.145 0.160 MOLD AND DIE STEEL (122-182) 300M, 4340, 52100, ≤ 655 Bhn Feed (mm/min) 967 1289 1386 1122 1192 1102 1168 773 HP-9-4-20, M50, A2, or D2, H13, L2, M2, P20, ≤ 60 HRc 305 RPM 97005 64670 32335 19401 16168 9701 8084 4850 S7, T15, W2 HSM ≤ 0.4 ≤ 0.01 Fz 0.013 0.023 0.048 0.064 0.081 0.127 0.160 0.180 (244-366) Feed (mm/min) 2522 2975 3104 2483 2619 2464 2587 1746 Bhn (Brinell) HRc (Rockwell C) HSM (High Speed Machining) rpm = (Vc x 1000) / (D1 x 3.14) mm/min = Fz x 2 x rpm reduce speed and feed for materials harder than listed reduce feed and Ae when finish milling (.02 x D1 maximum) refer to the KYOCERA SGS Tool Wizard® for complete technical information (www.kyocera-sgstool.com) www.kyocerEaN-DsgMstILoLoSl.com END MILLS 107

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском