Общий каталог SGS 2018 - страница 106

Навигация

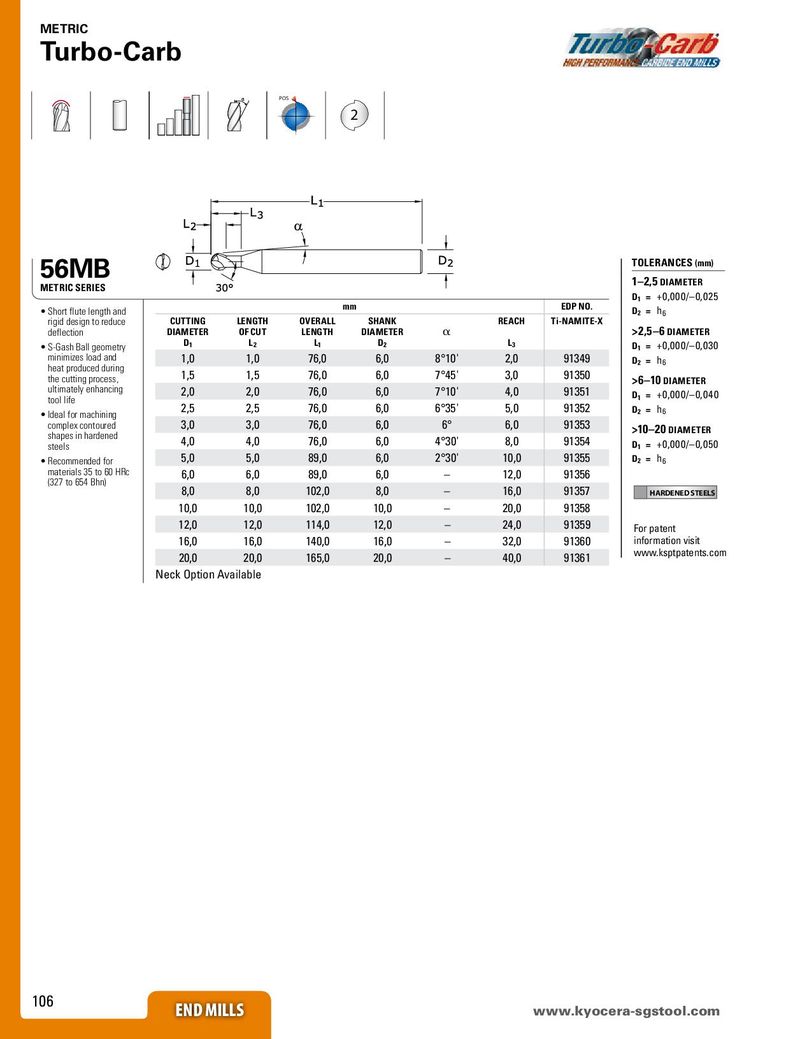

METRIC Turbo-Carb POS 2 56MB TOLERANCES (mm) METRIC SERIES 1–2,5 DIAMETER D1 = +0,000/–0,025 • Short flute length and mm EDP NO. D2 = h6 rigid design to reduce CUTTING LENGTH OVERALL SHANK α REACH Ti-NAMITE-X >2,5–6 DIAMETER deflection DIAMETER OF CUT LENGTH DIAMETER • S-Gash Ball geometry D1 L2 L1 D2 L3 D1 = +0,000/–0,030 minimizes load and 1,0 1,0 76,0 6,0 8°10' 2,0 91349 D2 = h6 heat produced during 1,5 1,5 76,0 6,0 7°45' 3,0 91350 the cutting process, >6–10 DIAMETER ultimately enhancing 2,0 2,0 76,0 6,0 7°10' 4,0 91351 D1 = +0,000/–0,040 tool life 2,5 2,5 76,0 6,0 6°35' 5,0 91352 h6 • Ideal for machining D2 = complex contoured 3,0 3,0 76,0 6,0 6° 6,0 91353 >10–20 DIAMETER shapes in hardened 4,0 4,0 76,0 6,0 4°30' 8,0 91354 D1 = +0,000/–0,050 steels • Recommended for 5,0 5,0 89,0 6,0 2°30' 10,0 91355 D2 = h6 materials 35 to 60 HRc 6,0 6,0 89,0 6,0 – 12,0 91356 (327 to 654 Bhn) 8,0 8,0 102,0 8,0 – 16,0 91357 HARDENED STEELS 10,0 10,0 102,0 10,0 – 20,0 91358 12,0 12,0 114,0 12,0 – 24,0 91359 For patent 16,0 16,0 140,0 16,0 – 32,0 91360 information visit 20,0 20,0 165,0 20,0 – 40,0 91361 www.ksptpatents.com Neck Option Available 106 END MILLS wwwE.kNyDoMceILraLS-sgstool.com

Каталог SGS шестизубые фрезы T-carb

Каталог SGS шестизубые фрезы T-carb Каталог SGS микро инструмент 2021

Каталог SGS микро инструмент 2021 Каталог SGS фрезы для алюминия S-carb

Каталог SGS фрезы для алюминия S-carb Каталог SGS высокопроизводительные черновые фрезы

Каталог SGS высокопроизводительные черновые фрезы Каталог SGS инструмент для обработки алюминия

Каталог SGS инструмент для обработки алюминия Общий каталог SGS 2015 на русском

Общий каталог SGS 2015 на русском