Общий каталог Mitsubishi 2020 - 2021 - страница 1280

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

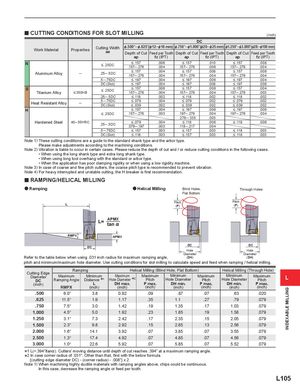

y CUTTING CONDITIONS FOR SLOT MILLING ( inch) DC Work Material Properties Cutting Width &.500"─&.625"(&12─&16 mm) &.750"─&1.000"(&20─&25 mm) &1.250"─&3.000"(&28─&100 mm)aeDepth of CutFeed per ToothDepth of CutFeed per ToothDepth of CutFeed per Tooth ap fz (IPT) ap fz (IPT) ap fz (IPT) N < .25DC < .157.157─.276 .006.004 < .157.157─.276 .010.006 < .157.157─.276 .008.004 Aluminum Alloy ─ .25─.5DC < .157.157─.276 .004.004 < .157.157─.276 .008.004 < .157.157─.276 .008.004 .5─.75DC < .197 .004 < .197 .006 < .197 .004 DC (Slot) < .197 .004 < .197 .008 < .197 .006 S Titanium Alloy < 350HB < .25DC < .157.157─.276 .006.004 < .157.157─.276 .006.004 < .157.157─.276 .004.003 .25─.5DC < .118 .002 < .118 .002 < .118 .002 Heat Resistant Alloy ─ .5─.75DC < .079 .004 < .079 .002 < .079 .002DC (Slot)< .039.002< .039.002< .039.002 H < .157 .004 < .197 .006 < .197 .006 < .25DC .157─.276 .003 .197─.276 .004 .197─.276 .004 .276─.335 .003 Hardened Steel 40─55HRC .25─.5DC < .079.079─.197 .004.003 < .118.118─.217 .006.004 < .118 .006 .5─.75DC < .157 .003 < .157 .003 < .118 .003 DC (Slot) < .118 .003 < .157 .003 < .118 .003 Note 1) These cutting conditions are a guide to the standard shank type and the arbor type. Please make adjustments according to the machining conditions. Note 2) Vibration is liable to occur in certain cases. Please reduce the depth of cut and / or reduce cutting conditions in the following cases. • When using the long shank type and extra long shank type. • When using long tool overhang with the standard or arbor type. • When the application has poor clamping rigidity or when using a low rigidity machine. Note 3) In case of coarse and fine pitch cutters, the coarse pitch type is recommended to prevent vibration. Note 4) For heavy interrupted and unstable cutting, the H breaker is first recommendation. y RAMPING/HELICAL MILLING a Ramping a Helical Milling Blind Holes, Through Holes Flat Bottom Pitch Pitch (P) (P) APMX RMPX APMX DC DC DC Hole Hole Diameter Diameter Refer to the table below when using .031 inch radius for maximum ramping angle, (DH) (DH) pitch and minimum/maximum hole diameter. Use cutting conditions for slot milling to calculate speed and feed when ramping / helical milling. Cutting EdgeDiameterDC(inch)RampingMaximumMinimumRamping AngleDistance L *1RMPX(inch)Helical Milling (Blind Hole, Flat Bottom)MaximumMaximumMinimumMaximumHole Diameter *2PitchHole DiameterPitchDH max.P max.DH min.P max.(inch)(inch)(inch)(inch) Helical Milling (Through Hole)MinimumMaximumHole DiameterPitchDH min.P max.(inch)(inch)L .500 6.0° 3.8 0.92 .09 .87 .07 .63 .020 .625 11.5° 1.9 1.17 .35 1.1 .27 .79 .079 .750 7.5° 3.0 1.42 .19 1.35 .17 1.03 .079 1.000 4.5° 5.0 1.92 .23 1.85 .19 1.58 .079 1.250 3.1° 7.3 2.42 .17 2.35 .15 2.05 .079 1.500 2.3° 9.8 2.92 .15 2.85 .13 2.56 .079 2.000 1.6° 14.1 3.92 .07 3.85 .07 3.55 .079 2.500 1.3° 17.4 4.92 .07 4.85 .07 4.56 .079 3.000 1.0° 22.6 5.92 .07 5.85 .07 5.52 .079 **12 L(=.394"/tan%). Cutters' moving distance until depth of cut reaches .394" at In case corner radius of .031". Other than that, find with the below formula. {(cutting edge diameter DC) - (corner radius) - .008"} x 2 a maximum ramping angle. Note 1) When machining highly ductile materials with ramping angles above, chips could be continuous. In this case, decrease the ramping angle or feed per tooth. L105 INDEXABLE MILLING