Общий каталог Mitsubishi 2020 - 2021 - страница 1256

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

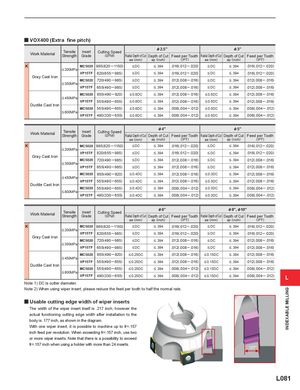

y VOX400 (Extra fine pitch) Work Material Tensile InsertStrengthGradeCutting Speed & 2.5" & 3"(SFM)Radial Depth of CutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.6DC < .394 .012(.008 ─ .016) < 0.5DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.6DC < .394 .012(.008 ─ .016) < 0.5DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.6DC < .394 .008(.004 ─ .012) < 0.5DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < 0.6DC < .394 .008(.004 ─ .012) < 0.5DC < .394 .008(.004 ─ .012) Work Material Tensile InsertStrengthGradeCutting Speed & 4" & 5"(SFM)Radial Depth of CutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.4DC < .394 .012(.008 ─ .016) < 0.3DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.4DC < .394 .012(.008 ─ .016) < 0.3DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.4DC < .394 .008(.004 ─ .012) < 0.3DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < 0.4DC < .394 .008(.004 ─ .012) < 0.3DC < .394 .008(.004 ─ .012) Work Material Tensile InsertStrengthGradeCutting Speed & 6" & 8", &10"(SFM)Radial Depth of CutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.25DC < .394 .012(.008 ─ .016) < 0.15DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.25DC < .394 .012(.008 ─ .016) < 0.15DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.25DC < .394 .008(.004 ─ .012) < 0.15DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < 0.25DC < .394 .008(.004 ─ .012) < 0.15DC < .394 .008(.004 ─ .012) L Note 1) DC is cutter diameter. Note 2) When using wiper insert, please reduce the feed per tooth to half the normal rate. y Usable cutting edge width of wiper inserts The width of the wiper insert itself is .217 inch, however the actual functioning cutting edge width after installation to the body is .177 inch, as shown in the diagram. With one wiper insert, it is possible to machine up to fr=.157 inch feed per revolution. When exceeding fr=.157 inch, use two or more wiper inserts. Note that there is a possibility to exceed fr=.157 inch when using a holder with more than 24 inserts. .157" L081 INDEXABLE MILLING