Общий каталог Mitsubishi 2020 - 2021 - страница 1255

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

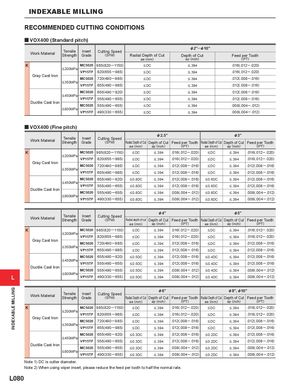

INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS y VOX400 (Standard pitch) Work Material Tensile InsertStrengthGradeCutting Speed(SFM)Radial Depth of Cut & 2"─ & 10"Depth of Cut Feed per Tooth ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < DC < .394 .008(.004 ─ .012) y VOX400 (Fine pitch) Work Material Tensile InsertStrengthGradeCutting Speed & 2.5" & 3"(SFM)Radial Depth of CutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.8DC < .394 .012(.008 ─ .016) < 0.6DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.8DC < .394 .012(.008 ─ .016) < 0.6DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.8DC < .394 .008(.004 ─ .012) < 0.6DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < 0.8DC < .394 .008(.004 ─ .012) < 0.6DC < .394 .008(.004 ─ .012) Work Material Tensile InsertStrengthGrade & 4" & 5"Cutting Speed(SFM)Radial depth of cutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.5DC < .394 .012(.008 ─ .016) < 0.4DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.5DC < .394 .012(.008 ─ .016) < 0.4DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.5DC < .394 .008(.004 ─ .012) < 0.4DC < .394 .008(.004 ─ .012) < 800MPa L VP15TF 490(330 ─ 655) < 0.5DC < .394 .008(.004 ─ .012) < 0.4DC < .394 .008(.004 ─ .012) Work Material Tensile InsertStrengthGrade & 6" & 8", &10"Cutting Speed(SFM)Radial Depth of CutDepth of CutFeed per ToothRadial Depth of CutDepth of CutFeed per Tooth ae (mm) ap (inch) (IPT) ae (mm) ap (inch) (IPT) K MC5020 985(820 ─ 1150) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) < 200MPa VP15TF 820(655 ─ 985) < DC < .394 .016(.012 ─ .020) < DC < .394 .016(.012 ─ .020) Gray Cast Iron MC5020 720(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) < 350MPa VP15TF 655(490 ─ 985) < DC < .394 .012(.008 ─ .016) < DC < .394 .012(.008 ─ .016) MC5020 655(490 ─ 820) < 0.3DC < .394 .012(.008 ─ .016) < 0.2DC < .394 .012(.008 ─ .016) < 450MPa VP15TF 555(490 ─ 655) < 0.3DC < .394 .012(.008 ─ .016) < 0.2DC < .394 .012(.008 ─ .016) Ductile Cast Iron MC5020 555(490 ─ 655) < 0.3DC < .394 .008(.004 ─ .012) < 0.2DC < .394 .008(.004 ─ .012) < 800MPa VP15TF 490(330 ─ 655) < 0.3DC < .394 .008(.004 ─ .012) < 0.2DC < .394 .008(.004 ─ .012) Note 1) DC is cutter diameter. Note 2) When using wiper insert, please reduce the feed per tooth to half the normal rate. L080 INDEXABLE MILLING