Общий каталог Mitsubishi 2020 - 2021 - страница 1217

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

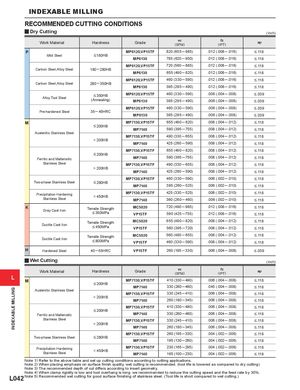

INDEXABLE MILLING RECOMMENDED CUTTING CONDITIONS y Dry Cutting ( inch) Work Material Hardness Grade vc(SFM) fz(IPT) ap P MP6120,VP15TF 820 (655 ─ 985) .012 (.008 ─ .016) <.118 Mild Steel <180HB MP6130 785 (620 ─ 950) .012 (.008 ─ .016) <.118 MP6120,VP15TF 720 (560 ─ 885) .012 (.008 ─ .016) <.118 Carbon Steel,Alloy Steel 180 ─ 280HB MP6130 655 (490 ─ 820) .012 (.008 ─ .016) <.118 MP6120,VP15TF 460 (330 ─ 590) .012 (.008 ─ .016) <.118 Carbon Steel,Alloy Steel 280 ─ 350HB MP6130 395 (295 ─ 490) .012 (.008 ─ .016) <.118 Alloy Tool Steel < 350HB MP6120,VP15TF 460 (330 ─ 590) .006 (.004 ─ .008) <.039(Annealing)MP6130395 (295 ─ 490).006 (.004 ─ .008)<.039 MP6120,VP15TF 460 (330 ─ 590) .006 (.004 ─ .008) <.039 Pre-hardened Steel 35 ─ 45HRC MP6130 395 (295 ─ 490) .006 (.004 ─ .008) <.039 M MP7130,VP15TF 655 (490 ─ 820) .008 (.004 ─ .012) <.118 < 200HB MP7140 590 (395 ─ 755) .008 (.004 ─ .012) <.118 Austenitic Stainless Steel MP7130,VP15TF 490 (330 ─ 655) .008 (.004 ─ .012) <.118 > 200HB MP7140 425 (260 ─ 590) .008 (.004 ─ .012) <.118 MP7130,VP15TF 655 (490 ─ 820) .008 (.004 ─ .012) <.118 < 200HB Ferritic and Maltensitic MP7140 590 (395 ─ 755) .008 (.004 ─ .012) <.118 Stainless Steel MP7130,VP15TF 490 (330 ─ 655) .008 (.004 ─ .012) <.118 > 200HB MP7140 425 (260 ─ 590) .008 (.004 ─ .012) <.118 MP7130,VP15TF 460 (330 ─ 590) .006 (.002 ─ .010) <.118 Two-phase Stainless Steel < 280HB MP7140 395 (260 ─ 525) .006 (.002 ─ .010) <.118 Precipitation HardeningStainless Steel MP7130,VP15TF 425 (330 ─ 525) .006 (.002 ─ .010) <.118< 450HBMP7140360 (260 ─ 460).006 (.002 ─ .010)<.118 K Gray Cast Iron Tensile Strength MC5020 720 (490 ─ 985) .012 (.008 ─ .016) <.118< 350MPaVP15TF590 (425 ─ 755).012 (.008 ─ .016)<.118 Ductile Cast Ilon Tensile Strength MC5020 655 (490 ─ 820) .008 (.004 ─ .012) <.118< 450MPaVP15TF560 (395 ─ 720).008 (.004 ─ .012)<.118 Ductile Cast Ilon Tensile Strength MC5020 560 (490 ─ 655) .008 (.004 ─ .012) <.118< 800MPaVP15TF460 (330 ─ 590).008 (.004 ─ .012)<.118 H Hardened Steel 40 ─ 55HRC VP15TF 260 (195 ─ 330) .006 (.004 ─ .008) <.039 y Wet Cutting ( inch) Work Material Hardness Grade vc(SFM) fz(IPT) ap L M MP7130,VP15TF 410 (330 ─ 490) .006 (.004 ─ .008) <.118< 200HB MP7140 330 (260 ─ 460) .045 (.004 ─ .008) <.118 Austenitic Stainless Steel MP7130,VP15TF 330 (245 ─ 410) .006 (.004 ─ .008) <.118 > 200HB MP7140 260 (180 ─ 345) .006 (.004 ─ .008) <.118 MP7130,VP15TF 410 (330 ─ 490) .006 (.004 ─ .008) <.118 < 200HB Ferritic and Maltensitic MP7140 330 (260 ─ 460) .006 (.004 ─ .008) <.118 Stainless Steel MP7130,VP15TF 330 (245 ─ 410) .006 (.004 ─ .008) <.118 > 200HB MP7140 260 (180 ─ 345) .006 (.004 ─ .008) <.118 MP7130,VP15TF 260 (195 ─ 330) .004 (.002 ─ .006) <.118 Two-phase Stainless Steel < 280HB MP7140 195 (130 ─ 260) .004 (.002 ─ .006) <.118 Precipitation HardeningStainless Steel MP7130,VP15TF 230 (165 ─ 295) .004 (.002 ─ .006) <.118< 450HBMP7140165 (100 ─ 230).004 (.002 ─ .006)<.118 Note 1) Refer to the above table and set up cutting conditions according to cutting applications. Note 2) When placing emphasis on surface finish quality, wet cutting is recommended. (tool life is lowered as compared to dry cutting) Note 3) The recommended depth of cut differs according to insert geometry. Note 4) When clamp rigidity is low and tool overhang is long, we recommended to reduce the cutting speed and the feed rate by 30%. L042 Note 5) Recommended wet cutting for good surface finishing of stainless steel. (Tool life is short compared to wet cutting.) INDEXABLE MILLING