Общий каталог Mitsubishi 2020 - 2021 - страница 1216

Навигация

Каталог Mitsubishi Materials запасные части

Каталог Mitsubishi Materials запасные части Каталог Mitsubishi Materials резьбонарезной инструмент

Каталог Mitsubishi Materials резьбонарезной инструмент Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки

Каталог Mitsubishi Materials СНП с CBN и PCD для токарной обработки Каталог Mitsubishi Materials сверлильные инструменты

Каталог Mitsubishi Materials сверлильные инструменты Каталог Mitsubishi Materials расточной инструмент

Каталог Mitsubishi Materials расточной инструмент Каталог Mitsubishi Materials пластины для точения

Каталог Mitsubishi Materials пластины для точения

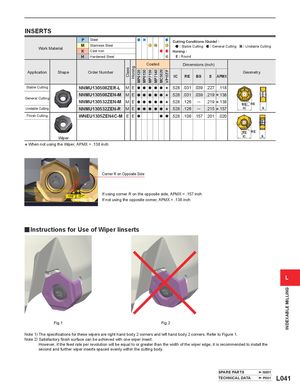

Class Honing MP6120 MP6130 MP7130 MP7140 MC5020 VP15TF INDEXABLE MILLING INSERTS P Steel Cutting Conditions (Guide) : Work Material M Stainless SteelKCast Iron : Stable Cutting : General Cutting : Unstable CuttingHoning : H Hardened Steel E : Round Coated Dimensions (inch) Application Shape Order Number Geometry IC RE BS S APMX Stable Cutting NNMU130508ZER-L M E a a a a a s .528 .031 .039 .227 .118 General Cutting NNMU130508ZEN-M M E a a a a a s .528 .031 .039 .219 *.138 NNMU130532ZEN-M M E a a a a a s .528 .126 ─ .219 *.138 BS RE Unstable Cutting NNMU130532ZEN-R M E a a a a a s .528 .126 ─ .215 *.157 IC S Finish Cutting WNEU1305ZEN4C-M E E a a a .528 .106 .157 .201 .020 BS RE Wiper IC S * When not using the Wiper, APMX = .138 inch Corner R on Opposite Side .138" .157" If using corner R on the opposite side, APMX = .157 inch If not using the opposite corner, APMX = .138 inch yInstructions for Use of Wiper Iinserts L Fig.1 Fig.2 Note 1) The specifications for these wipers are right hand body 2 corners and left hand body 2 corners. Refer to Figure 1. Note 2) Satisfactory finish surface can be achieved with one wiper insert. However, if the feed rate per revolution will be equal to or greater than the width of the wiper edge, it is recommended to install the second and further wiper inserts spaced evenly within the cutting body. SPARE PARTS N001 TECHNICAL DATA P001 L041