Каталог Iscar вращающийся инструмент 2017 - страница 54

Навигация

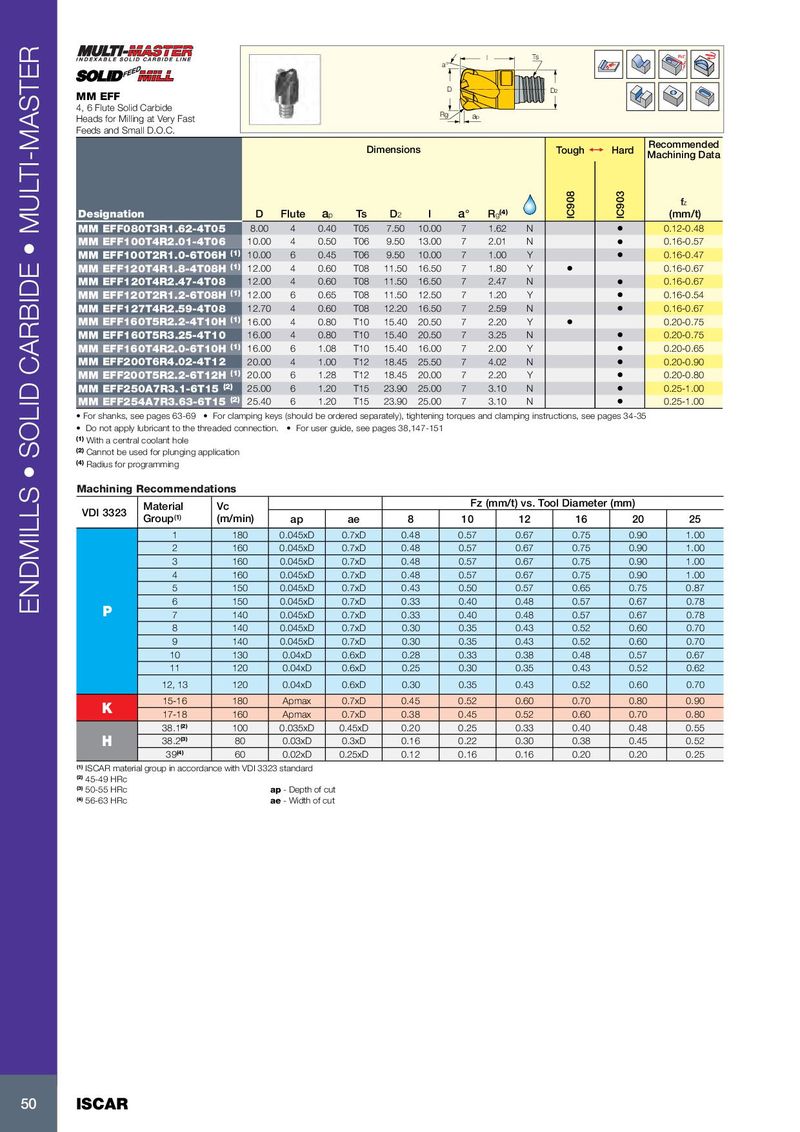

l Ts Rd° a° D D2 MM EFF 4, 6 Flute Solid Carbide Rg Heads for Milling at Very Fast ap Feeds and Small D.O.C. Recommended Dimensions Tough 1 Hard Machining Data f z Designation D Flute a p Ts D 2 l a° R g (4) IC908 IC903 (mm/t) MM EFF080T3R1.62-4T05 8.00 4 0.40 T05 7.50 10.00 7 1.62 N • 0.12-0.48 MM EFF100T4R2.01-4T06 10.00 4 0.50 T06 9.50 13.00 7 2.01 N • 0.16-0.57 MM EFF100T2R1.0-6T06H (1) 10.00 6 0.45 T06 9.50 10.00 7 1.00 Y • 0.16-0.47 MM EFF120T4R1.8-4T08H (1) 12.00 4 0.60 T08 11.50 16.50 7 1.80 Y • 0.16-0.67 MM EFF120T4R2.47-4T08 12.00 4 0.60 T08 11.50 16.50 7 2.47 N • 0.16-0.67 MM EFF120T2R1.2-6T08H (1) 12.00 6 0.65 T08 11.50 12.50 7 1.20 Y • 0.16-0.54 MM EFF127T4R2.59-4T08 12.70 4 0.60 T08 12.20 16.50 7 2.59 N • 0.16-0.67 MM EFF160T5R2.2-4T10H (1) 16.00 4 0.80 T10 15.40 20.50 7 2.20 Y • 0.20-0.75 MM EFF160T5R3.25-4T10 16.00 4 0.80 T10 15.40 20.50 7 3.25 N • 0.20-0.75 MM EFF160T4R2.0-6T10H (1) 16.00 6 1.08 T10 15.40 16.00 7 2.00 Y • 0.20-0.65 MM EFF200T6R4.02-4T12 20.00 4 1.00 T12 18.45 25.50 7 4.02 N • 0.20-0.90 MM EFF200T5R2.2-6T12H (1) 20.00 6 1.28 T12 18.45 20.00 7 2.20 Y • 0.20-0.80 MM EFF250A7R3.1-6T15 (2) 25.00 6 1.20 T15 23.90 25.00 7 3.10 N • 0.25-1.00 MM EFF254A7R3.63-6T15 (2) 25.40 6 1.20 T15 23.90 25.00 7 3.10 N • 0.25-1.00 • For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • Do not apply lubricant to the threaded connection. • For user guide, see pages 38,147-151 (1) With a central coolant hole (2) Cannot be used for plunging application (4) Radius for programming Machining Recommendations Material Vc Fz (mm/t) vs. Tool Diameter (mm) VDI 3323 Group (1) (m/min) ap ae 8 10 12 16 20 25 1 180 0.045xD 0.7xD 0.48 0.57 0.67 0.75 0.90 1.00 2 160 0.045xD 0.7xD 0.48 0.57 0.67 0.75 0.90 1.00 3 160 0.045xD 0.7xD 0.48 0.57 0.67 0.75 0.90 1.00 4 160 0.045xD 0.7xD 0.48 0.57 0.67 0.75 0.90 1.00 5 150 0.045xD 0.7xD 0.43 0.50 0.57 0.65 0.75 0.87 6 150 0.045xD 0.7xD 0.33 0.40 0.48 0.57 0.67 0.78 ENDMILLS • SOLID CARBIDE • MULTI-MASTER P 7 140 0.045xD 0.7xD 0.33 0.40 0.48 0.57 0.67 0.78 8 140 0.045xD 0.7xD 0.30 0.35 0.43 0.52 0.60 0.70 9 140 0.045xD 0.7xD 0.30 0.35 0.43 0.52 0.60 0.70 10 130 0.04xD 0.6xD 0.28 0.33 0.38 0.48 0.57 0.67 11 120 0.04xD 0.6xD 0.25 0.30 0.35 0.43 0.52 0.62 12, 13 120 0.04xD 0.6xD 0.30 0.35 0.43 0.52 0.60 0.70 15-16 180 Apmax 0.7xD 0.45 0.52 0.60 0.70 0.80 0.90 K 17-18 160 Apmax 0.7xD 0.38 0.45 0.52 0.60 0.70 0.80 38.1 (2) 100 0.035xD 0.45xD 0.20 0.25 0.33 0.40 0.48 0.55 H 38.2 (3) 80 0.03xD 0.3xD 0.16 0.22 0.30 0.38 0.45 0.52 39 (4) 60 0.02xD 0.25xD 0.12 0.16 0.16 0.20 0.20 0.25 (1) ISCAR material group in accordance with VDI 3323 standard (2) 45-49 HRc (3) 50-55 HRc ap - Depth of cut (4) 56-63 HRc ae - Width of cut 50 ISCAR

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022