Каталог Iscar вращающийся инструмент 2017 - страница 53

Навигация

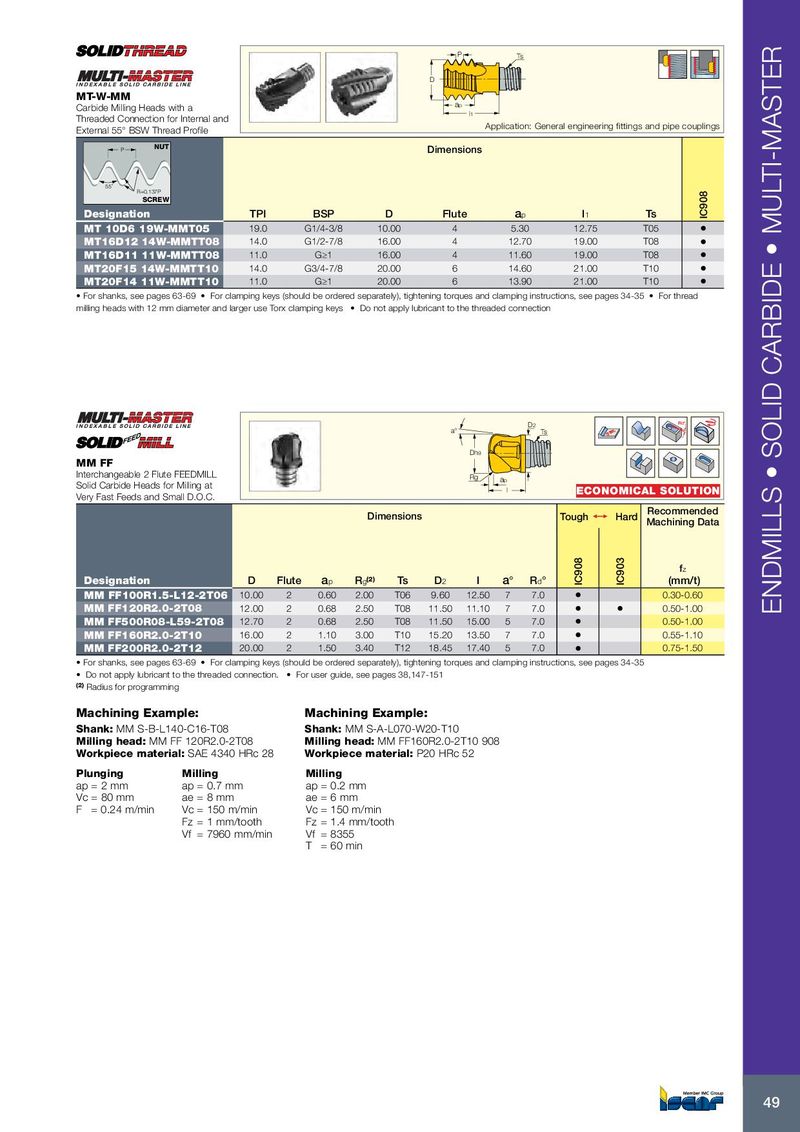

P Ts D MT-W-MM Carbide Milling Heads with a ap l1 Threaded Connection for Internal and Application: General engineering fittings and pipe couplings External 55° BSW Thread Profile P NUT Dimensions 55˚ R=0.137P SCREW Designation TPI BSP D Flute a p l 1 Ts IC908 MT 10D6 19W-MMT05 19.0 G1/4-3/8 10.00 4 5.30 12.75 T05 • MT16D12 14W-MMTT08 14.0 G1/2-7/8 16.00 4 12.70 19.00 T08 • MT16D11 11W-MMTT08 11.0 G≥1 16.00 4 11.60 19.00 T08 • MT20F15 14W-MMTT10 14.0 G3/4-7/8 20.00 6 14.60 21.00 T10 • MT20F14 11W-MMTT10 11.0 G≥1 20.00 6 13.90 21.00 T10 • • For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • For thread milling heads with 12 mm diameter and larger use Torx clamping keys • Do not apply lubricant to the threaded connection D2 Rd° a° Ts Dh9 MM FF Interchangeable 2 Flute FEEDMILL Rg ap Solid Carbide Heads for Milling at l ECONOMICAL SOLUTION Very Fast Feeds and Small D.O.C. Recommended Dimensions Tough 1 Hard Machining Data f z Designation D Flute a p R g (2) Ts D 2 l a° R d ° IC908 IC903 (mm/t) MM FF100R1.5-L12-2T06 10.00 2 0.60 2.00 T06 9.60 12.50 7 7.0 • 0.30-0.60 MM FF120R2.0-2T08 12.00 2 0.68 2.50 T08 11.50 11.10 7 7.0 • • 0.50-1.00 ENDMILLS • SOLID CARBIDE • MULTI-MASTER MM FF500R08-L59-2T08 12.70 2 0.68 2.50 T08 11.50 15.00 5 7.0 • 0.50-1.00 MM FF160R2.0-2T10 16.00 2 1.10 3.00 T10 15.20 13.50 7 7.0 • 0.55-1.10 MM FF200R2.0-2T12 20.00 2 1.50 3.40 T12 18.45 17.40 5 7.0 • 0.75-1.50 • For shanks, see pages 63-69 • For clamping keys (should be ordered separately), tightening torques and clamping instructions, see pages 34-35 • Do not apply lubricant to the threaded connection. • For user guide, see pages 38,147-151 (2) Radius for programming Machining Example: Machining Example: Shank: MM S-B-L140-C16-T08 Shank: MM S-A-L070-W20-T10 Milling head: MM FF 120R2.0-2T08 Milling head: MM FF160R2.0-2T10 908 Workpiece material: SAE 4340 HRc 28 Workpiece material: P20 HRc 52 Plunging Milling Milling ap = 2 mm ap = 0.7 mm ap = 0.2 mm Vc = 80 mm ae = 8 mm ae = 6 mm F = 0.24 m/min Vc = 150 m/min Vc = 150 m/min Fz = 1 mm/tooth Fz = 1.4 mm/tooth Vf = 7960 mm/min Vf = 8355 T = 60 min 49

Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar решения для глубокого сверления

Каталог Iscar решения для глубокого сверления Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022