Каталог Iscar токарные пластины ISO 2022 - страница 90

Навигация

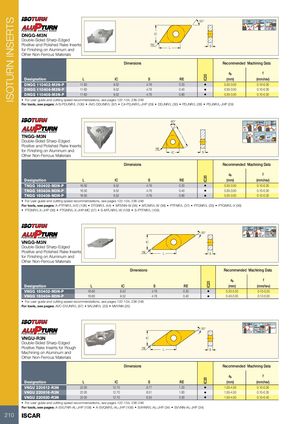

ISOTURN INSERTS IC20IC20IC20 IC20 55° 60°MAX 27°MAX 93º-95º 62.5º 93º 50º MAX DNGG-M3N IC Double-Sided Sharp-Edged Positive and Polished Rake Insertsfor Finishing on Aluminum and RE L S Other Non-Ferrous Materials Dimensions Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) DNGG 110402-M3N-P 11.63 9.52 4.76 0.20 • 0.30-3.00 0.10-0.30 DNGG 110404-M3N-P 11.63 9.52 4.76 0.40 • 0.30-3.00 0.10-0.30 DNGG 110408-M3N-P 11.63 9.52 4.76 0.80 • 0.30-3.00 0.10-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PDUNR/L (106) • AVC-DDUNR/L (97) • C#-PDJNR/L-JHP (29) • DDJNR/L (30) • PDJNR/L (28) • PDJNR/L-JHP (29) 60° 22°MAX 55°MAX 91º 93º 60º TNGG-M3N L 91º 91º 95º Double-Sided Sharp-Edged Positive and Polished Rake Inserts for Finishing on Aluminum and RE IC S Other Non-Ferrous Materials Dimensions Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) TNGG 160402-M3N-P 16.50 9.52 4.76 0.20 • 0.30-3.00 0.10-0.30 TNGG 160404-M3N-P 16.50 9.52 4.76 0.40 • 0.30-3.00 0.10-0.30 TNGG 160408-M3N-P 16.50 9.52 4.76 0.80 • 0.30-3.00 0.10-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-PTFNR/L-X/G (108) • DTGNR/L (44) • MTENN-W (38) • MTJNR/L-W (38) • PTFNR/L (37) • PTGNR/L (35) • PTGNR/L-X (36) • PTGNR/L-X-JHP (36) • PTGNR/L-X-JHP-MC (37) • S-MTLNR/L-W (109) • S-PTFNR/L (109) 50°MAX 70°MAX 30° 35° MAX 93° 72.5º 93º VNGG-M3N IC Double-Sided Sharp-Edged Positive and Polished Rake Inserts RE L S for Finishing on Aluminum and Other Non-Ferrous Materials Dimensions Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) VNGG 160402-M3N-P 16.60 9.52 4.76 0.20 • 0.20-3.00 0.10-0.25 VNGG 160404-M3N-P 16.60 9.52 4.76 0.40 • 0.40-3.00 0.12-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: AVC-DVUNR/L (97) • MVJNR/L (33) • MVVNN (35) 70°MAX 35° 35° MAX 107.5º 72.5º 107.5º VNGU-R3N IC Double-Sided Sharp-Edged Positive Rake Inserts for Rough RE L S Machining on Aluminum and Other Non-Ferrous Materials Dimensions Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) VNGU 220612-R3N 22.00 12.70 6.77 1.20 • 1.00-4.50 0.10-0.30 VNGU 220616-R3N 22.00 12.70 6.51 1.60 • 1.50-4.50 0.10-0.35 VNGU 220630-R3N 22.00 12.70 6.35 3.00 • 1.50-4.50 0.15-0.40 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A-SVLFNR-AL-JHP (108) • A-SVQNR/L-AL-JHP (108) • SVHNR/L-AL-JHP (34) • SVVNN-AL-JHP (34) 210 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022