Каталог Iscar токарные пластины ISO 2022 - страница 88

Навигация

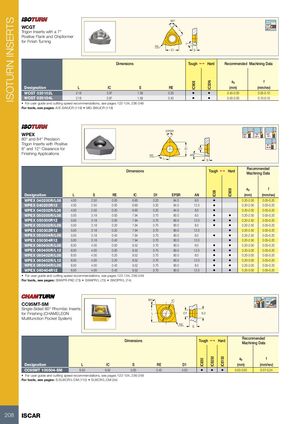

ISOTURN INSERTS IC908 IC830 IC30N IC08IC8250 IC8150 IC908 80° 93º WCGTTrigon Inserts with a 7° L Positive Flank and Chipformer for Finish Turning 7° RE IC S Dimensions Tough 1 Hard Recommended Machining Data ap f Designation L IC S RE (mm) (mm/rev) WCGT 020102L 2.18 3.97 1.59 0.20 • • 0.40-2.00 0.05-0.10 WCGT 020104L 2.18 3.97 1.59 0.40 • • 0.40-2.00 0.10-0.15 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/E-SWUCR (119) • MG-SWUCR (119) EPSR WPEX 90° 75° 60° 80° and 84° Precision Trigon Inserts with Positive 45° 8° and 12° Clearance for IC D1 Finishing Applications RE AN° L S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L S RE IC D1 EPSR AN (mm) (mm/rev) WPEX 040200R/L08 4.00 2.50 0.00 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20 WPEX 040200R12 4.00 2.50 0.00 6.60 3.20 84.0 12.0 • 0.20-2.00 0.05-0.20 WPEX 040202R/L08 4.00 2.50 0.20 6.60 3.20 84.0 8.0 • 0.20-2.00 0.05-0.20 WPEX 050300R/L08 5.00 3.18 0.00 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20 WPEX 050300R12 5.00 3.18 0.00 7.94 3.70 80.0 12.0 • • 0.20-2.50 0.05-0.20 WPEX 050302R/L08 5.00 3.18 0.20 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20 WPEX 050302R12 5.00 3.18 0.20 7.94 3.70 80.0 12.0 • 0.20-2.50 0.05-0.20 WPEX 050304R/L08 5.00 3.18 0.40 7.94 3.70 80.0 8.0 • • 0.20-2.50 0.05-0.20 WPEX 050304R12 5.00 3.18 0.40 7.94 3.70 80.0 12.0 • 0.20-2.50 0.05-0.20 WPEX 060400R/L08 6.00 4.00 0.00 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20 WPEX 060400R/L12 6.00 4.00 0.00 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20 WPEX 060402R/L08 6.00 4.00 0.20 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20 WPEX 060402R/L12 6.00 4.00 0.20 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20 WPEX 060404R/L08 6.00 4.00 0.40 9.52 3.70 80.0 8.0 • • 0.20-3.00 0.05-0.20 WPEX 060404R12 6.00 4.00 0.40 9.52 3.70 80.0 12.0 • • 0.20-3.00 0.05-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: SWAPR-PAD (73) • SWAPR/L (73) • SWDPR/L (74) CC95MT-SM 80° IC 95º 95º95º Single-Sided 80° Rhombic Inserts for Finishing (CHAMELEON L D1 6.2 Multifunction Pocket System) RE S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE D1 (mm) (mm/rev) CC95MT 100504-SM 9.50 9.52 5.00 0.40 4.50 • • • 0.50-3.00 0.07-0.24 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: S-SUXCR/L-CM (110) • SUXCR/L-CM (54) 208 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022