Каталог Iscar токарные пластины ISO 2022 - страница 106

Навигация

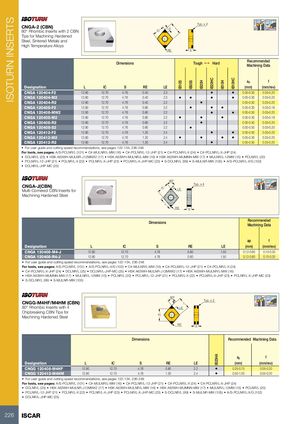

ISOTURN INSERTS IB10S IB05S IB20H IB20HC IB25HA IB10H IB10HC 95º CNGA-2 (CBN)80° Rhombic Inserts with 2 CBN Typ. x 2 95ºICLEL95º Tips for Machining Hardened Steel, Sintered Metals and High Temperature Alloys RE S Dimensions Tough 1 Hard RecommendedMachining Data ap f Designation L IC S RE LE (mm) (mm/rev) CNGA 120404-F2 12.90 12.70 4.76 0.40 2.3 • • 0.05-0.50 0.05-0.20 CNGA 120404-M2 12.90 12.70 4.76 0.40 2.3 • • • • 0.05-0.30 0.05-0.20 CNGA 120404-R2 12.90 12.70 4.76 0.40 2.2 • 0.05-0.50 0.05-0.20 CNGA 120408-F2 12.90 12.70 4.76 0.80 2.2 • • • 0.05-0.30 0.05-0.18 CNGA 120408-MW2 12.90 12.70 4.76 0.80 2.2 • • 0.05-0.50 0.05-0.20 CNGA 120408-M2 12.90 12.70 4.76 0.80 2.2 • • • 0.05-0.30 0.05-0.18 CNGA 120408-R2 12.90 12.70 4.76 0.80 2.2 • 0.05-0.50 0.05-0.20 CNGA 120408-S2 12.90 12.70 4.76 0.80 2.2 • 0.05-0.50 0.05-0.20 CNGA 120412-F2 12.90 12.70 4.76 1.20 2.4 • • 0.05-0.50 0.05-0.20 CNGA 120412-M2 12.90 12.70 4.76 1.20 2.4 • • • • 0.05-0.30 0.05-0.20 CNGA 120412-R2 12.90 12.70 4.76 1.20 2.4 • 0.05-0.50 0.05-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCLNR/L (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) • A/S-PCLNR/L-X/G (102) • DCLNR/L-JHP-MC (25) 80º 95º CNGA-J(CBN)Multi-Cornered CBN Inserts for Typ. x 4 95ºICLE95º Machining Hardened Steel L RE S Dimensions RecommendedMachining Data ap f Designation L IC S RE LE (mm) (mm/rev) CNGA 120408-M4-J 12.90 12.70 4.76 0.80 1.50 0.12-0.80 0.10-0.30 CNGA 120408-R4-J 12.90 12.70 4.76 0.80 1.50 0.12-0.80 0.10-0.30 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • A/S-PCLNR/L-X/G (102) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCLNR/L (25) • DCLNR/L-JHP-MC (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) 80º 95º CNGG-M4HF/M4HM (CBN) Typ. x 2 95ºL95º 80° Rhombic Inserts with 4 LE Chipbreaking CBN Tips for Machining Hardened Steel IC RE S Dimensions Recommended Machining Data ap f Designation L IC S RE LE (mm) (mm/rev) CNGG 120408-M4HF 12.90 12.70 4.76 0.80 2.2 • 0.20-0.75 0.05-0.20 CNGG 120412-M4HM 12.90 12.70 4.76 1.20 2.4 • 0.50-1.00 0.05-0.20 • For user guide and cutting speed recommendations, see pages 122-134, 236-248 For tools, see pages: A/S-PCLNR/L (101) • C#-MULNR/L-MW (16) • C#-PCLNR/L-12-JHP (21) • C#-PCLNR/L-X (24) • C#-PCLNR/L-X-JHP (24) • DCLNR/L (25) • HSK A63WH-MULNR-J12MWX2 (17) • HSK A63WH-MULNR/L-MW (16) • HSK A63WH-MUMNN-MW (17) • MULNR/L-12MW (15) • PCLNR/L (20) • PCLNR/L-12-JHP (21) • PCLNR/L-X (22) • PCLNR/L-X-JHP (23) • PCLNR/L-X-JHP-MC (23) • S-DCLNR/L (99) • S-MULNR-MW (105) • A/S-PCLNR/L-X/G (102) • DCLNR/L-JHP-MC (25) 226 ISCAR

Каталог Iscar инструмент для обработки отверстий

Каталог Iscar инструмент для обработки отверстий Каталог Iscar инструмент для токарной обработки

Каталог Iscar инструмент для токарной обработки Каталог Iscar концевые фрезы со сменными пластинами 2022

Каталог Iscar концевые фрезы со сменными пластинами 2022 Каталог Iscar инструментальные блоки

Каталог Iscar инструментальные блоки Каталог Iscar торцевые фрезы 2022

Каталог Iscar торцевые фрезы 2022