Каталог Iscar сверла ружейные и для глубокого сверления 2022 - страница 105

Навигация

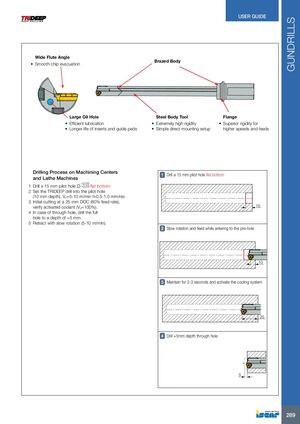

GUNDRILLS USER GUIDE Wide Flute Angle • Smooth chip evacuation Brazed Body Large Oil Hole Steel Body Tool Flange • Efficient lubrication • Extremely high rigidity • Superior rigidity for • Longer life of inserts and guide pads • Simple direct mounting setup higher speeds and feeds Drilling Process on Machining Centersand Lathe Machines 1 Drill a 15 mm pilot hole flat bottom 1 Drill a 15 mm pilot hole D +0.05 +0.03 flat bottom 2 Set the TRIDEEP drill into the pilot hole (10 mm depth). Vc=5-10 m/min f=0.5-1.0 mm/rev 3 Initial cutting at a 25 mm DOC (80% feed rate), verify activated coolant (Vc=100%). 15 4 In case of through hole, drill the full hole to a depth of +5 mm. 5 Retract with slow rotation (5-10 m/min). 2 Slow rotation and feed while entering to the pre-hole 10 3 Maintain for 2-3 seconds and activate the cooling system 25 4 Drill +5mm depth through hole 5 289

Каталог Iscar новые продукты 2018

Каталог Iscar новые продукты 2018 Каталог Iscar полирующие фрезы

Каталог Iscar полирующие фрезы Каталог Iscar инструмент для фрезерования

Каталог Iscar инструмент для фрезерования Каталог Iscar инструмент для нарезания резьбы

Каталог Iscar инструмент для нарезания резьбы Каталог Iscar токарные державки ISO 2022

Каталог Iscar токарные державки ISO 2022 Каталог Iscar монолитные концевые фрезы и система multi-master

Каталог Iscar монолитные концевые фрезы и система multi-master