Каталог Iscar концевые фрезы со сменными пластинами 2022 - страница 88

Навигация

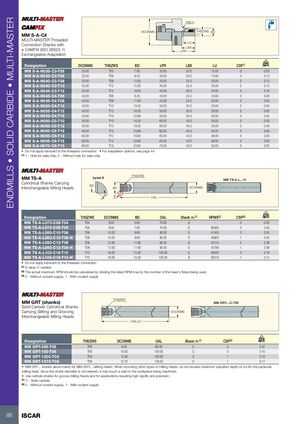

ENDMILLS • SOLID CARBIDE • MULTI-MASTER RE5.0 DCONMS THSZWS BD MM S-A-C# MULTI-MASTER Threaded Connection Shanks with LU a CAMFIX (ISO 26623-1) LBXLPR Exchangeable Adaptation Designation DCONMS THSZWS BD LPR LBX LU CDI(1) kg MM S-A-H035-C3-T05 32.00 T05 7.60 35.00 20.0 15.00 0 0.00 MM S-A-H035-C3-T06 32.00 T06 9.25 35.00 20.0 15.00 0 0.12 MM S-A-H040-C3-T08 32.00 T08 11.60 40.00 25.0 20.00 0 0.13 MM S-A-H040-C3-T10 32.00 T10 15.30 40.00 25.0 20.00 0 0.15 MM S-A-H045-C3-T12 32.00 T12 18.30 45.00 30.0 25.00 0 0.16 MM S-A-H045-C4-T06 40.00 T06 9.25 45.00 25.0 20.00 0 0.00 MM S-A-H045-C4-T08 40.00 T08 11.60 45.00 25.0 20.00 0 0.00 MM S-A-H050-C4-T10 40.00 T10 15.30 50.00 30.0 25.00 0 0.00 MM S-A-H055-C4-T12 40.00 T12 18.30 55.00 35.0 30.00 0 0.00 MM S-A-H055-C4-T15 40.00 T15 23.90 55.00 35.0 30.00 0 0.35 MM S-A-H060-C5-T10 50.00 T10 15.30 60.00 40.0 35.00 0 0.00 MM S-A-H060-C5-T12 50.00 T12 18.30 60.00 40.0 35.00 0 0.48 MM S-A-H060-C5-T15 50.00 T15 23.90 60.00 40.0 35.00 0 0.58 MM S-A-H065-C6-T12 63.00 T12 18.30 65.00 43.0 38.00 0 0.00 MM S-A-H065-C6-T15 63.00 T15 23.90 65.00 43.0 38.00 0 0.00 MM S-A-H070-C8-T15 80.00 T15 23.90 70.00 40.0 35.00 0 0.00 • Do not apply lubricant to the threaded connection • For adaptation options, see page 44 (1) 1 - Hole for data chip, 0 - Without hole for data chip MM TS-A Detail B THSZWS MM TS-A-L...-H Cylindrical Shanks Carrying Interchangeable Milling Heads BD BD DCONMS 30˚ B OAL Designation THSZWS DCONMS BD OAL Shank m.(1) RPMX(2) CSP(3) kg MM TS-A-L070-C08-T04 T04 8.00 5.80 70.00 S - 0 0.00 MM TS-A-L070-C08-T05 T05 8.00 7.60 70.00 S 60000 0 0.03 MM TS-A-L080-C10-T06 T06 10.00 9.60 80.00 S 47400 0 0.05 MM TS-A-L080-C10-T06-H T06 10.00 9.60 80.00 S 46920 1 0.04 MM TS-A-L090-C12-T08 T08 12.00 11.60 90.00 S 43110 0 0.08 MM TS-A-L090-C12-T08-H T08 12.00 11.60 90.00 S 42780 1 0.08 MM TS-A-L100-C16-T10 T10 16.00 15.30 100.00 S 39420 0 0.16 MM TS-A-L100-C16-T10-H T10 16.00 15.30 100.00 S 39210 1 0.14 • Do not apply lubricant to the threaded connection (1) S-steel, C-carbide (2) The actual maximum RPM should be calculated by dividing the listed RPM max by the number of the head's flutes being used. (3) 0 - Without coolant supply, 1 - With coolant supply THSZWS MM GRT (shanks) MM GRT-...C-T08 Solid Carbide Cylindrical Shanks Carrying Slitting and Grooving DCONMS Interchangeable Milling Heads OAL/LF Designation THSZWS DCONMS OAL Shank m.(1) CSP(2) kg MM GRT-095-T06 T06 9.52 80.00 C 0 0.07 MM GRT-100-T06 T06 10.00 100.00 C 0 0.10 MM GRT-120C-T08 T08 12.00 100.00 C 1 0.12 MM GRT-127C-T08 T08 12.70 120.00 C 1 0.17 • MM GRT... shanks serve mainly for MM GRIT... slitting heads. When mounting other types of milling heads, do not exceed maximum specified depth of cut for the particular milling head. Since the shank diameter is not relieved, it may touch a wall on the workpiece being machined. • Use carbide shanks for groove milling heads and for applications requiring high rigidity and precision. (1) C - Solid carbide (2) 0 - Without coolant supply, 1 - With coolant supply 86 ISCAR

Каталог Iscar токарный инструмент

Каталог Iscar токарный инструмент Каталог Iscar токарные пластины ISO 2022

Каталог Iscar токарные пластины ISO 2022 Каталог Iscar высокоточные развертки и метчики 2022

Каталог Iscar высокоточные развертки и метчики 2022 Каталог Iscar крепление инструмента

Каталог Iscar крепление инструмента Каталог Iscar сверла ружейные и для глубокого сверления 2022

Каталог Iscar сверла ружейные и для глубокого сверления 2022 Каталог Iscar инструментальная оснастка 2022

Каталог Iscar инструментальная оснастка 2022