Общий каталог Dijet 2018 - страница 34

Навигация

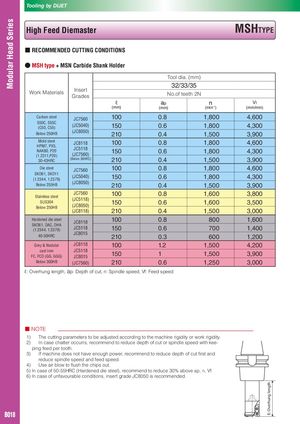

Modular Head Series ℓ: Overhung length MMoodduullaarr HHeeaaddSSeerireiess Tooling by DIJET High Feed Diemaster MSHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSH type + MSN Carbide Shank Holder Tooling by DIJET Tool dia. (mm) HWiogrkhMFaeteeriadlsDieGImnrasdeaerstster 32/33/35No.of teeth 2N MSHTYPE ℓ ap n Vf (mm)■ RECOMMENDED CUTTING CONDITIONS (mm) (min-1) (mm/min) Carbon steel JC7560 100 0.8 1,800 4,600 ● MSS(5CH05C0t,,ySCp5555eC) + MSN(JCC5a04rb0)ide Shank1H5o0lder 0.6 1,800 4,300 Below 250HB (JC8050) 210 0.4Tool dia. (mm) 1,500 3,900 Mold steelHPM7, PX5,WorNkAKM80a, Pte20rials(1.2311,P20)JJInCC85s11e11r88t(GJCra75d6e0s)100 16/17 0.8150No. of teeth 2N 0.6 1,80020/21/22 4,6001,8N0o0. of teeth 2N4,300 30-43HRC (Below 36HRC) ℓ 210 ap n 0.4 Vf ℓ 1,50a0p n 3,900Vf Die steel JC7560 (mm) 100(mm) (min-1) 0.(8mm/min) (mm) 1,80(m0m) (min-1)4,6(0m0m/min) SCKaDrb61o,nSsKtDe1e1l(1.S25304C4,, 1S.5253C79)B(eClo5w0,2C5555H)BBelow 250HBSMtaionledsstseteelel(BN1He.AP2lSoM3KUw18S71023,,5,0PPP04XH22500B,)30-43HRC(JJCC57054600)70 150 0.4((JJCC85005400))(JC8050)JC7560(JJCC55111188)((JJCC87055600))120 210 0.3160 70 100 0.2 0.4120 150 0.3(B(eJlCow81361H8R)C)160 210 0.23,580 0.66,440701,8000.63,180 0.45,0901201,5000.52,980 3,180 0.845,,776200190701,60000..353,180 0.65,0901201,6000.42,980 0.44,7601901,5000.32,8504,3050,7002,6003,9050,20022,,4805003,80450,,8700002,6003,5050,2002,4003,0040,800 HardDeniedstdeieelsteelSSKKDD616,1D, ASCK,DD1H1A((11..22344, 1.22337799))Be4l0o-w502H5R5CHBJJC8715168070 100 0.4(JJC5101480)120 150 0.3(JJCC88001550)160 210 0.23,180 0.85,720 70 8000.53,180 0.65,0901207000.42,980 0.34,7601906000.32,8501,6050,7002,6001,4050,2002,4001,2040,800 GStraeyin&leNssodstuelaerlcSaUsSt 3ir0o4nFCB, eFCloDw(G2G5,0GHGBG)JJC87151680(JJCC55111188)(JJCC88001550)70 120 160 100 150 0.3 0.3 0.23,180 2,980 2,980 11.2544,,,777266000 7012019011,,550000000...543 222,,,54400000043,,290054400,,,088000000 ℓ: HarBdeelnowed30d0ieHBsteel OSKv(1eD.2r6h314u,4Dn,g1A.C2le,3D7n9Hg)Ath, 40-50HRC (JC7560) apJJ:CCD58e10p11th85of 70 210 0.2 cu1t,2n0: Spindle0.s2peed, 160 – 2,380 0.62,610 V2f,:3F8ee0d sp2ee,3d80 – – 70 1,2500.4120 0.3190–1,3003,0010,6001,2001,400–– Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HB JC5118JC8015(JC7560) 70120160 0.5 2,980 6,550 700.42,9805,9601200.32,5005,000190 0.6 2,400 5,8000.52,4005,3000.42,0004,800 ℓ : Overhung length, ap : Depth of cut, n : Spindle speed, Vf : Feed speed ■■ NNOOTTEE 112))) TheTIcnhuectatcisnuegttcipnhagaratptmearreaotmecrcesutterorrssb,teroeacbdoejumasmdtejeudnsadteccdtooarrdceicdnougrcdteoindtghetepotmhthaoecfhmciunatecohrriignsiepdiirntigydiolderitswypooerrekwdroigwrikidthritigyk.iedeit-y. 2)Ipnincagsfeecehdaptteerr toococtuhr.rs, recommend to reduce depth of cut or spindle speed with keeping 3) feedIfpmear ctohointeh.does not have enough power, recommend to reduce depth of cut first and 3)If mraecdhuinceedsopeinsdnloetshpaeveedeannodugfehepdoswpeere, rde.commend to reduce depth of cut first and reduce 4) spinUdsleesapireebdloawntdoffeluesdhsptheeecdh. ips out. 4565)))) UIIInnnsceccaaaasissereebooolfoff5wu50n0-t5of-a55fvH5louHRusCRhraC(tHbh(aleHerdcacherodinnpeedsndioetiduoditne.dssi,etiensestlee),errtle)g,crroaemdceommJeCmn8de0nt5od0rteoisdrureecdceuo3cm0em%3e0an%bdoeavdbe.oavpe, nap, V, nf., Vf. 6)In case of unfavourable conditions, insert grade JC8050 is recommended. B018

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском