Общий каталог Dijet 2018 - страница 35

Навигация

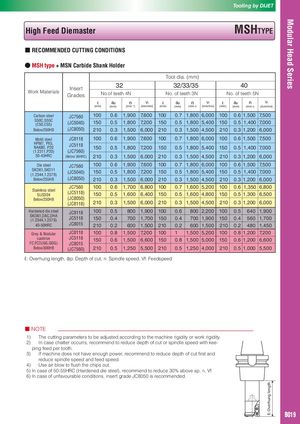

Modular Head SerieMMsoodduullaarr HHeeaaddSSeerireiess Tooling by DIJET High Feed Diemaster MSHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSH type + MSN Carbide Shank Holder Tooling by DIJET Tool dia. (mm) HWoirgkhMaFteeriaelsd DGiIenrasmdeertas ster No.of 32 teeth 4N 32/33/35No. of teeth 3N MSH No. of 40 teeth 5NTYPE ℓ ap n Vf ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min -1) (mm/min) (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) ■ RCEarCboOnMsteMel ENDEDJCC75U6T0TING10C0OND0IT.6ION1S,900 7,600 100 0.7 1,800 6,000 100 0.6 1,500 7,500 ● S50C,S55C M(SC5H0,Ct5y5p)e Below250HB + M((SJJCCN5800C45a00r))bide1251S00hank00..H53old11e,,85r 0000 7,2006,000 150210 0.5 1,800 5,400 150 0.5 1,400 7,0000.31,5004,5002100.3 1,2006,000 Mold steel JC8118 100 0.6 1,900 7,600 100Too0l .d7ia.1(,m80m0 )6,000 100 0.6 1,500 7,500 HPM7, PX5, W(oN1.Ar2Kk381M01,,PPa22t00e) rials 30-43HRC JC5In11s8ert (B(eJloCwG735r6a6H0dR)Ce) s 150210 0.5 1,80106/17,7200 1500.3N1o,.5o0f0tee6,t0h020N2100.51,8005,400 2105/021/02.52 1,400 7,0000.31,5004,500No.2o1f0tee0th.321N,2006,000 Die steelSKD61,SKD11(1.2C3a4r4b,o1.n23s7te9e) lBeSlo5w02C5, 5SH5B5C(C50, C55)StBaeinlloewss2s5te0eHl BBeHSMloUPwoMS2l3d5700,s4HPteXBe5l,NAK80, P20JC7560100(mℓm) 0.6(1ma,mp90) 07,6(m0ni0n-1)10(0mmV/fm0i.n7)1,8(m0ℓm0 ) 6,000(mamp10) 0 0(m.6nin1-1),500(m7m,V5/fm00in)(JC5040)(JC8JC05705)60(JC5040)150 70 0.5210120 0.301.,84007,32,05080 1506,4400.51,80700 5,4000.615001.,530063,0,10080 2105,0900.31,510200 4,5000.521020.,58510,400 57,,70000020.,36010,200 56,2,00000JC(7JC5680050)(JC5118)(JC8JC05501)18(JC(8JC11785)60)100160 0.6150 70 0.5210120 0.301.,720062,8,90080 1004,7600.71,610900 5,2000.310001.,640063,4,10080 1505,7200.51,60700 4,8000.515001.,530063,0,10080 2105,0900.31,510200 4,5000.421020.,64010,350 46,8,8000020.,58510,300 56,7,5000020.,36010,200 56,2,00000 HSaKrDd(1e63n.120e,3Dd-41Ad31CiHe,,DPRsH2tCe0Ae)l(1.23D44ie,1s.2t3e7e9l )S4K0D-5601H, RSCKD11(1.2344, 1.2379)GrBeyel&owNo2d5u5laHr BcastironFC,SFtCaDin(GleGs,sGsGtGe)elJ(CBe8lo1w1836HRC) 100160 0.50.820012,9,90080 1004,7600.6810900 2,2000.3100 02.,5400640 41,8,90000JC5118JC8JC0175560(JC5040)150 70 0.4210120 0.20.74000.630013,7,10080 1505,7200.413,5,10080 2105,0900.270700 1,9000.515002.,4850560 51,7,70000610200 1,5000.421002.,2600480 51,2,40500JC(8JC1188050)JC5118JC8JC0175560100160 0.8150 70 0.601.,520001.,53007,22,09080 1004,76101,510900 5,2000.310063,6,10080 1505,7200.81,50700 5,0000.515020.,84010,200 47,,82000020.,65010,200 56,0,60000 BeloSwU3S030H04B (JC(7JC56501)18) 210120 0.5 01.,2350 52,5,90080 2104,7600.5 1,215200 4,0000.4210 20.,54010,000 45,8,50000 ℓ: Below 250HB Overhung length, ap(:JDC8e0p5th0)of cu1t,6n0: Spindle0.s2peed, V2f,:9F8ee0dspe4e,d760 190 0.3 2,400 4,800 Hardened die steelSKD61, DAC, DHA JC5118(1.2344,1.2379)JC801540-50HRC 70120160 0.2 2,380 2,610 700.22,3802,380120–––190 0.4 1,300 1,6000.31,2001,400––– Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HB JC5118JC8015(JC7560) 70120160 0.5 2,980 6,550 700.42,9805,9601200.32,5005,000190 0.6 2,400 5,8000.52,4005,3000.42,0004,800 ℓ : Overhung length, ap : Depth of cut, n : Spindle speed, Vf : Feed speed ■■ NNOOTTEE 112))) TheTIcnhuectatcisnuegttcipnhagaratptmearreaotmecrcesutterorrssb,teroeacbdoejumasmdtejeudnsadteccdtooarrdceicdnougrcdteoindtghetepotmhthaoecfhmciunatecohrriignsiepdiirntigydiolderitswypooerrekwdroigwrikidthritigyk.iedeit-y. 2)Ipnincagsfeecehdaptteerr toococtuhr.rs, recommend to reduce depth of cut or spindle speed with keeping 3) feedIfpmear ctohointeh.does not have enough power, recommend to reduce depth of cut first and 3)If mraecdhuinceedsopeinsdnloetshpaeveedeannodugfehepdoswpeere, rde.commend to reduce depth of cut first and reduce 4) spinUdsleesapireebdloawntdoffeluesdhsptheeecdh. ips out. 4565)))) UIIInnnsceccaaaasissereebooolfoff5wu50n0-t5of-a55fvH5louHRusCRhraC(tHbh(aleHerdcacherodinnpeedsndioetiduoditne.dssi,etiensestlee),errtle)g,crroaemdceommJeCmn8de0nt5od0rteoisdrureecdceuo3cm0em%3e0an%bdoeavdbe.oavpe, nap, V, nf., Vf. 6)In case of unfavourable conditions, insert grade JC8050 is recommended. B019 ℓ: Overhung length

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском