Общий каталог Dijet 2018 - страница 33

Навигация

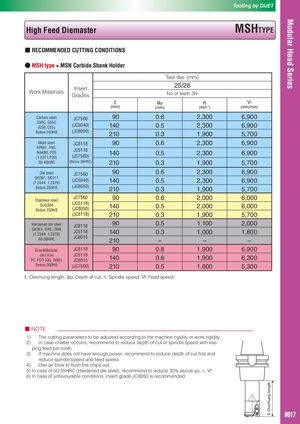

Modular Head SerieMMsoodduullaarr HHeeaaddSSeerireiess Tooling by DIJET High Feed Diemaster MSHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSH type + MSN Carbide Shank Holder Tooling by DIJET Tool dia. (mm) HWiogrkhMFaeteeriadlsDieGImnrasdeaerstster 25/26No.of teeth 3N MSHTYPE ℓ ap n Vf (mm) (mm) (min-1) (mm/min) ■ RECOMMENDED Carbon steel CUTTING JC7560 CONDITIONS 90 0.6 2,300 6,900 ● MSS(C5H05C0t,,yCSp5555e)C+ MSN(JCC5a04rb0)ide Shan1k4H0older 0.5 2,300 6,900 Below 250HB (JC8050) 210 0.3 Tool dia. (mm1),900 5,700 Mold steelWoHNrkPAMKM870,a,PPtXe250r, ials(1.2311,P20) (GJJJInCCCr785as511de611re088ts) 90 16/17 0.6140 No. of teeth 2N0.5 2,300 20/21/226,9002,300No. of teeth 26N,900 30-43HRC (Below 36HRC) ℓ 210 ap n 0.3 Vf ℓ1,900 ap n5,700 Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) (1SBCB.KSe2(ae5CDl3Dlroo0465biwweC410o,,s,,n221StSC5e5.sK5552e0tD5l5H3eHC17)eBB19l ) ((((JJJJJJCCCCCC587758005500456645000000)))) 70 90 0.41201400.31602100.23,5800.6 6,440 720,300 0.63,1800.5 5,0901220,300 0.52,9800.3 4,7601910,900 0.32,865,09005,7002,660,09005,2002,450,07004,800 Mold steelSHtaPinMle7s,sPsXte5e,lNASKU8S03,0P420(B1e.2lo3w1125, P0H20B)30-43HRC JJCC75516108 70 90 0.4((JJCC57151680))(B(eJlCow80365H0R)C)(JC8118)1201400.31602100.23,1800.6 5,720 720,000 0.53,1800.5 5,0901220,000 0.42,9800.3 4,7601910,900 0.32,865,00005,7002,660,00005,2002,450,07004,800 Die steelHSarKdDen6e1d, SdKieDs1te1elS(1K.D26314,4D, A1C.2,3D7H9A)(1B.e2l3o4w4, 215.253H7B9)40-50HRCStainless steelJC7560(JJCC85101480)7012090 0.40.3(JJCC58101580)JC8015JC75601601400.2702100.333,,1188000.5 5,720 5,090 127100,100 0.5 0.42,9800.3 4,7601910,000 0.33,180 –5,72070 –0.522,,86250,0000055,,7200002,410,08004,8002,500–5,000 GreSyU&SN3o0d4ular (JJCC85111188) 120 90 0.3 2,9800.8 4,760 1210,900 0.4 2,460,09004,800 ℓ: Belcoawst 2ir5o0nHB FC, FCD (GG, GGG) HarBdeelonwed30d0ieHBsteel SKD61, DAC, DHA Ov(1e.2r4h304u-54n0,g1H.2Rle3Cn79g)th, (JJC58101580) JC8015 (JJCC57516108) apJ:CD8e0p1th5of 160140 0.2 70210 0.2 120 0.2 cu1t,6n0: Spindle–speed, 2,9800.6 4,760 2,3800.5 2,610 2,380 2,380 Vf:–Feed speed– 1910,900 0.3710,600 0.41200.3190–2,460,03004,8001,350,03001,6001,2001,400–– Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HB JC5118JC8015(JC7560) 70120160 0.5 2,980 6,550 700.42,9805,9601200.32,5005,0001900.62,4005,8000.52,4005,3000.42,0004,800 ℓ : Overhung length, ap : Depth of cut, n : Spindle speed, Vf : Feed speed ■■ NNOOTTEE 112))) TheTIcnhuectatcisnuegttcipnhagaratptmearreaotmecrcesutterorrssb,teroeacbdoejumasmdtejeudnsadteccdtooarrdceicdnougrcdteoindtghetepotmhthaoecfhmciunatecohrriignsiepdiirntigydiolderitswypooerrekwdroigwrikidthritigyk.iedeit-y. 2)Ipnincagsfeecehdaptteerr toococtuhr.rs, recommend to reduce depth of cut or spindle speed with keeping 3) feedIfpmear ctohointeh.does not have enough power, recommend to reduce depth of cut first and 3)If mraecdhuinceedsopeinsdnloetshpaeveedeannodugfehepdoswpeere, rde.commend to reduce depth of cut first and reduce 4) spinUdsleesapireebdloawntdoffeluesdhsptheeecdh. ips out. 4565)))) UIIInnnsceccaaaasissereebooolfoff5wu50n0-t5of-a55fvH5louHRusCRhraC(tHbh(aleHerdcacherodinnpeedsndioetiduoditne.dssi,etiensestlee),errtle)g,crroaemdceommJeCmn8de0nt5od0rteoisdrureecdceuo3cm0em%3e0an%bdoeavdbe.oavpe, nap, V, nf., Vf. 6)In case of unfavourable conditions, insert grade JC8050 is recommended. B017 ℓ: Overhung length

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском