Общий каталог Dijet 2018 - страница 32

Навигация

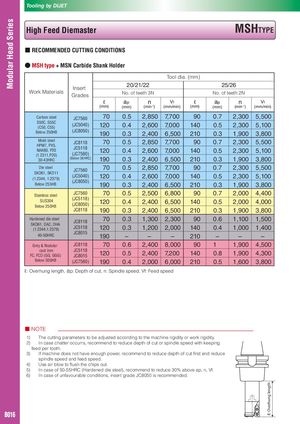

Modular Head Series ℓ: Overhung length MMoodduullaarr HHeeaaddSSeerireiess Tooling by DIJET High Feed Diemaster MSHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSH type + MSN Carbide Shank Holder Tooling by DIJET Tool dia. (mm) HWiogrkhMFaeteeriadlsDieGInmrsaedaretsster 20/21/22No. of teeth 3N No. MSH 25/26 of teeth 2N TYPE ℓ ap n Vf ℓ ap n Vf (mm) (mm) (min-1) (mm/min) (mm) (mm) (min-1) (mm/min) ■ RECOMMENDED Carbon steel CUTTING JC7560 CO7N0DITION0S.5 2,850 7,700 90 0.7 2,300 5,500 ● MSS(C5H05C0t,,yCSp5555e)C+ Below 250HB MSN(JCC5a04rb0)ide (JC8050) S1h2a0nk 190 Hold0e.r4 0.3 2,600 7,000 1402,4006T,o5o0l0dia. (m21m0)0.50.32,300 5,1001,9003,800 Mold steelHPM7, PX5,WoNrkAKM80a, Pte20rials(1.2311,P20)JC8118JICn5s1e1r8t(GJCr7a5d6e0s)701200.516/127,850 7,700N0o..4of tee2th,620N07,000 90140 0.270/21/22,3200 5,500N0o..5of tee2th,320N05,100 30-43HRC (Below 36HRC) 190ℓ 0a.p3 2,4n00 6,5Vf00 210ℓ 0a.p3 1,9n00 3,8V0f 0 Die steelSCKaDr6b1o, nSKstDe1e1l(1.S235404C,,1S.52357C9)Be(lCo5w02, 5C55H5B)Below 250HBStMainoleldssstseteeellHPSMUS73, 0P4X5,BNelAowK8205,0PH2B0JC7560(m7m0)(((JJJJCCCC5875005045640000)))(JC8050)JC75601720011290016700(JJCC55111188)((JJCC87055600))11722000(0m.m5)2(m,8in5-1)0(m7,m7/0m0in) (m9m0)0.423,56800076,,040400147000..3323,,14800065,,50900021120000000.....2435422233,,,,,91154888000000066455,,,,,85770629000000011149927000000(m.m7)2(m,3in0-10)(5m,m5/0m0in)00..5622,3805055,,1700000..3512,,96000035,,82000000000.....7535422222,,,,,00486000500000044455,,,,,408720000000000 (1.2311, P20)30-43HRC (BeJlCow81316H8RC) 116900 00..23 22,,948000 64,,576000 211900 00..33 12,,940000 34,,880000 HardenDeide dstieeestleelSKSDK6D16, 1D,ASCK, DD1H1A((11..22334444,,11.2.2337799) )Be4l0o-w502H5R5CHBJJCC871516807700(JJCC55101480)1200(JJCC88001550)11690000..4313,,13800025,,372000 97000.313,12800025,0900014200–.22,9–804,7–6021190000..6512,,18050015,,57000000..412,060015,,42000–.32,–4004,–800 GSretayi&nleNsosdsutlearel JJC87151680 7700 00..36 23,,148000 85,,072000 9700 10.5 12,,950000 45,,500000 ℓ: cSaUstSi3ro0n4 FC,BFeClDow(G2G5,0GHGBG) Below 300HB Hardened die steel OSvK(1eD.2r6h314u,4nD,g1A.C2le,3Dn79Hg)Ath, 40-50HRC (JJC55111188) (JJCC88001550) (JC7560) apJJ:CCD58e10p11th85of 111262000 000...325 17900 00..24 cu1t,2n0: Spindle0.s2peed, 160 – 222,,,994880000 22,,308000 V2f,:3F8ee0d – 744,,,277066000 62,,061000 spe2e,3d80 – 11142900021700120190000...843 122,,,944000000 444,,,38800000000..5411,,63000031,,8600000.31,2001,400––– Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HBJC5118JC8015(JC7560)70120160 0.5 2,980 6,550 700.42,9805,9601200.32,5005,0001900.62,400 5,8000.52,4005,3000.42,0004,800 ℓ : Overhung length, ap : Depth of cut, n : Spindle speed, Vf : Feed speed ■■ NNOOTTEE 1) The cutting parameters to be adjusted according to the machine rigidity or work rigidity. 12)) TheIcnuctatisnegcphaartatemreotcecrsurtros,breecaodmjumsteenddatcocorerddiuncgetdoetphtehmofacchutinoer rsipgiindditlye osrpweeodrkwriitghidkeiteyp. ing 2)Ifneecdaspeecrhtaotottehr. occurrs, recommend to reduce depth of cut or spindle speed with keeping 3) feedIfpmearctohionteh.does not have enough power, recommend to reduce depth of cut first and reduce 3)If msapchinidnleedsopeesendoatnhdavfeeeednsopuegehdp. ower, recommend to reduce depth of cut first and reduce 4) spinUdsle sapirebeldowantdo fleuesdh sthpeeecdh.ips out. 4556)))) UInsceaIIannsierccboaalssfoee5w0oo-tff5o5u50nfHl-fuRa5svC5hoH(utHRhraaCerbdc(lhHeeinacperosddnoedduniiettei.odsntdsei,eeilns),streeeerctl)og,mrraemdcoeemnJdCm8teo0n5dre0tdoisurcreeedc3uo0cm%em3ae0bn%odveaedba.opv,ena,pV,f.n, Vf. 6)In case of unfavourable conditions, insert grade JC8050 is recommended. B016

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском