Общий каталог Dijet 2018 - страница 31

Навигация

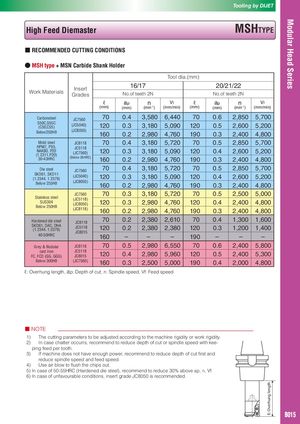

Modular Head SerieMMsoodduullaarr HHeeaaddSSeerireiess Tooling by DIJET High Feed Diemaster MSHTYPE ■ RECOMMENDED CUTTING CONDITIONS ● MSH type + MSN Carbide Shank Holder Tooling by DIJET Tool dia.(mm) HWiogrkhMFaeteeriadlsDieGImnrasdeaerstster 16/17No.of teeth 2N MSH 20/21/22No.of teeth 2N TYPE ℓ ap n Vf ℓ ap n Vf ■ RECOMMENDED Carbonsteel CUTTING JC7560 C(OmNmD) ITION(mSm) 70 0.4 (min-1) (mm/min) (mm)3,5806,44070(mm) (min-1) (mm/min)0.62,8505,700 ● MSS(H5C05C0t,,ySCp5555eC) + Below250HB MS(NJCC50a40r)bide (JC8050) S1h2a0nk 160 Hold0e.r3 0.2 3,180 5,090 1202,9804T,o7o6l0dia. (m19m0)0.50.3 2,600 5,2002,4004,800 Mold steelWoHNrkPAMKM870,a,PPtXe250r, ials(1.2311,P20)30-43HRC IJJnCC85s11e11r88t(BGe(JloCrwa735d66He0R)sC)701201ℓ600.416/137,180 5,720 70N0o..3of tee3th,128N05,0901200a.p22,9n804,7V6f 019ℓ00.250/212/2,82505,700N0o.4. of tee2t,h620N05,2000a.3p2,4n004,8V0f 0 Die steel JC7560 (m7m0) (0m.m4) 3(m,1in8-10) (m5,m7/2m0in) (m7m0) 0(m.m5) 2(,m8in5-10) (5m,m7/0m0in) SCKaDr6b1o,nSsKtDe1e1l(1B.S2(e5C3lo045wC40,,,21SC5.55525H53C7)B9)Below 250HBStMaionlledssstseteeel l(BN1He.AP2lSoM3KUw18S71203,5,,0PP0P4XH2250B0,)30-43HRC(JJCC75054600)17200((JJCC58005400))(JC8050)JC7560(JJCC55111188)((JJCC87055600))1126001776000112200(B(eJloCw813168H)RC)11660000..4333,,15880056,,0494001270000..3223,,91880045,,706900119200000...243323,,,191888000545,,,777262000179700000..3323,,91880045,,70690011220000..2222,,99880044,,77660011990000..4622,,68050055,,27000000..3522,,46000045,,820000000...535222,,,548005000545,,,08700000000..4422,,46000045,,82000000..3322,,44000044,,880000 HardDenieedstdeieelsteelSKSKDD616,1D, ASCK,DD1H1A((11..22334444,, 11..22337799))Be4l0o-w502H5R5CHBJJCC7851618070(JJCC55011480)112200(JJCC88001550)1166000.4223,3180025,67120 77000..3223,31880025,308900112200–.22,–9804,7–6011990000..4512,,3805015,,6700000..3412,,260015,,420000–.32,4–004,–800 FCGSB,trFeaeClcyiSonDaU&wsle(StGNs23irsGo50ods,n04tuGHelGaeBrGl ) (JJJJCCCC8575115111618808)(JJCC88001550)1772000116200000...335232,,,919888000654,,,577526000 172700000..2422,,99880054,,976600112900000...654222,,,454000000554,,,80800000000..5322,,44000054,,380000 ℓ: HarBdeelonwed30d0ieHBsteel OSvK(1eD.2r6h314u,4nD,g1A.C2le,3Dn79Hg)Ath, 40-50HRC (JC7560) apJJ:CCD58e10p11th85of 17600 00..23 cu1t,2n0: Spindle0.s2peed, 160 – 22,,538000 V2f,:3F8ee0d – 52,,060100 spe2e,3d80 – 19700120190 00..44 21,,030000 41,,8600000.31,2001,400––– Grey & Nodularcast ironFC, FCD (GG, GGG)Below 300HB JC5118JC8015(JC7560) 70120160 0.5 2,980 6,550 700.42,9805,9601200.32,5005,0001900.6 2,400 5,8000.52,4005,3000.42,0004,800 ℓ : Overhung length, ap : Depth of cut, n : Spindle speed, Vf : Feed speed ■■ NNOOTTEE 112))) TheTIcnhuectatcisnuegttcipnhagaratptmearreaotmecrcesutterorrssb,teroeacbdoejumasmdtejeudnsadteccdtooarrdceicdnougrcdteoindtghetepotmhthaoecfhmciunatecohrriignsiepdiirntigydiolderitswypooerrekwdroigwrikidthritigyk.iedeit-y. 2)Ipnincagsfeecehdaptteerr toococtuhr.rs, recommend to reduce depth of cut or spindle speed with keeping 3) feedIfpmear ctohointeh.does not have enough power, recommend to reduce depth of cut first and 3)If mraecdhuinceedsopeinsdnloetshpaeveedeannodugfehepdoswpeere, rde.commend to reduce depth of cut first and reduce 4) spinUdsleesapireebdloawntdoffeluesdhsptheeecdh. ips out. 4565)))) UIIInnnsceccaaaasissereebooolfoff5wu50n0-t5of-a55fvH5louHRusCRhraC(tHbh(aleHerdcacherodinnpeedsndioetiduoditne.dssi,etiensestlee),errtle)g,crroaemdceommJeCmn8de0nt5od0rteoisdrureecdceuo3cm0em%3e0an%bdoeavdbe.oavpe, nap, V, nf., Vf. 6)In case of unfavourable conditions, insert grade JC8050 is recommended. B015 ℓ: Overhung length

Общий каталог Dijet 2012 на русском

Общий каталог Dijet 2012 на русском