Общий каталог Yamawa 2021 - страница 262

Навигация

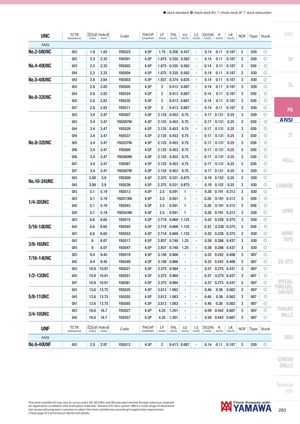

h stock standard, ) check stock EU, f check stock JP, m stock exhaustion UNC TCTR Ø Hole Ø(tolerance)(mm)(mm)CodeTHCHT(chamfer)LF(inch) THL(inch) LU(inch) LS DCON K(inch)(inch)(inch)LK(inch)NOFTypeStockIntro ANSI No.2-56UNC GH2 1.8 1.83 Y85523 4.5P 1.75 0.256 0.437 - 0.14 0.11 0.187 2 030 f GH2 2.3 2.33 Y85501 4.5P 1.875 0.335 0.562 - 0.14 0.11 0.187 2 030 f SP No.4-40UNC GH3 2.3 2.33 Y85502 4.5P 1.875 0.335 0.562 - 0.14 0.11 0.187 2 030 f GH4 2.3 2.33 Y85504 4.5P 1.875 0.335 0.562 - 0.14 0.11 0.187 2 030 f No.5-40UNC GH2 2.6 2.64 Y85503 4.5P 1.937 0.374 0.625 - 0.14 0.11 0.187 3 030 f GH3 2.8 2.83 Y85505 4.5P 2 0.413 0.687 - 0.14 0.11 0.187 3 030 f SL GH4 2.8 2.83 Y85524 4.5P 2 0.413 0.687 - 0.14 0.11 0.187 3 030 f No.6-32UNC GH5 2.8 2.83 Y85535 4.5P 2 0.413 0.687 - 0.14 0.11 0.187 3 030 f GH7 2.8 2.83 Y85511 4.5P 2 0.413 0.687 - 0.14 0.11 0.187 3 030 f PO GH3 3.4 3.47 Y85507 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH3 3.4 3.47 Y85507NI 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f ANSI GH4 3.4 3.47 Y85529 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH5 3.4 3.47 Y85537 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f ST No.8-32UNC GH5 3.4 3.47 Y85537NI 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH6 3.4 3.47 Y85560 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH6 3.4 3.47 Y85560NI 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH7 3.4 3.47 Y85567 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f ROLL GH7 3.4 3.47 Y85567NI 4.5P 2.125 0.453 0.75 - 0.17 0.131 0.25 3 030 f GH3 3.89 3.9 Y85509 4.5P 2.375 0.531 0.875 - 0.19 0.152 0.25 3 030 f No.10-24UNC GH5 3.89 3.9 Y85539 4.5P 2.375 0.531 0.875 - 0.19 0.152 0.25 3 030 f CARBIDE GH3 5.1 5.19 Y85513 4.5P 2.5 0.591 1 - 0.26 0.191 0.312 3 030 f GH3 5.1 5.19 Y85513NI 4.5P 2.5 0.591 1 - 0.26 0.191 0.312 3 030 f 1/4-20UNC GH5 5.1 5.19 Y85543 4.5P 2.5 0.591 1 - 0.26 0.191 0.312 3 030 f GH5 5.1 5.19 Y85543NI 4.5P 2.5 0.591 1 - 0.26 0.191 0.312 3 030 f LONG GH3 6.6 6.65 Y85515 4.5P 2.718 0.669 1.125 - 0.32 0.238 0.375 3 030 f 5/16-18UNC GH5 6.6 6.65 Y85545 4.5P 2.718 0.669 1.125 - 0.32 0.238 0.375 3 030 f GH7 6.6 6.65 Y85553 4.5P 2.718 0.669 1.125 - 0.32 0.238 0.375 3 030 f HAND GH3 8 8.07 Y85517 4.5P 2.937 0.748 1.25 - 0.38 0.286 0.437 3 030 f TAPS 3/8-16UNC GH5 8 8.07 Y85547 4.5P 2.937 0.748 1.25 - 0.38 0.286 0.437 3 030 f GH3 9.4 9.45 Y85519 4.5P 3.156 0.866 - - 0.32 0.242 0.406 3 007 f 7/16-14UNC GH5 9.4 9.45 Y85549 4.5P 3.156 0.866 - - 0.32 0.242 0.406 3 007 f EG (STI) GH3 10.9 10.91 Y85521 4.5P 3.375 0.984 - - 0.37 0.275 0.437 3 007 f 1/2-13UNC GH5 10.9 10.91 Y85551 4.5P 3.375 0.984 - - 0.37 0.275 0.437 3 007 f GH7 10.9 10.91 Y85581 4.5P 3.375 0.984 - - 0.37 0.275 0.437 3 007 f SPECIAL GH3 13.6 13.75 Y85525 4.5P 3.812 1.083 - - 0.48 0.36 0.562 3 007 f THREADS,GAUGES 5/8-11UNC GH5 13.6 13.75 Y85555 4.5P 3.812 1.083 - - 0.48 0.36 0.562 3 007 f GH7 13.6 13.75 Y85585 4.5P 3.812 1.083 - - 0.48 0.36 0.562 3 007 f GH3 16.6 16.7 Y85527 4.5P 4.25 1.201 - - 0.59 0.442 0.687 3 007 f THREAD 3/4-10UNC GH5 16.6 16.7 Y85557 4.5P 4.25 1.201 - - 0.59 0.442 0.687 3 007 f MILLS UNF TCTR Ø Hole Ø(tolerance)(mm)(mm)CodeTHCHT(chamfer)LF(inch) THL(inch) LU(inch) LS DCON K(inch)(inch)(inch)LK(inch)NOFTypeStock ANSI DIES No.6-40UNF GH2 2.9 2.97 Y85512 4.5P 2 0.413 0.687 - 0.14 0.11 0.187 3 030 f CENTER DRILLS Technical info The most suitable GH tap class to cut accurate 2B, 3B (UNJ) and 2B oversized internal threads tolerance, depends on application conditions and work-piece materials. Yamawa GH class system offers a wide range of alternative tap classes allowing each customer to select the most suitable one according to application requirement. 263 Check page 673 of Technical info for full details.

Обший каталог Yamawa 2016 - 2017

Обший каталог Yamawa 2016 - 2017 Краткое руководство Yamawa по каталогам

Краткое руководство Yamawa по каталогам Общий каталог Yamawa 2022 - 2023

Общий каталог Yamawa 2022 - 2023 Каталоги Yamawa твердосплавные метчики для закаленной стали

Каталоги Yamawa твердосплавные метчики для закаленной стали