Каталог Winstar монолитный инструмент 2020 - страница 271

Навигация

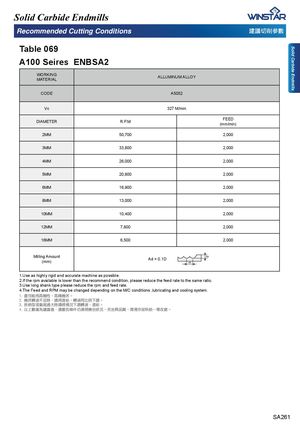

Solid Carbide Endmills Solid Carbide Endmills Recommended Cutting Conditions ら峿⎖⏙╒㜇 Table 069 A100 Seires ENBSA2 WORKINGMATERIAL ALLUMINUM ALLOY CODE A5052 Vc 327 M/min DIAMETER R.P.M FEED(mm/min) 2MM 50,700 2,000 3MM 33,800 2,000 4MM 26,000 2,000 5MM 20,800 2,000 6MM 16,900 2,000 8MM 13,000 2,000 10MM 10,400 2,000 12MM 7,800 2,000 16MM 6,500 2,000 Milling Amount(mm) Ad = 0.1D AdPf 1.Use as highly rigid and accurate machine as possible. 2.If the rpm available is lower than the recommend condition, please reduce the feed rate to the same ratio. 3.Use long shank type please reduce the rpm and feed rate. 4.The Feed and RPM may be changed depending on the M/C conditions ,lubricating and cooling system. 2/ 䡰╾劌䚷汧⏪ㆶҷ汧乍㯮〙Ҹ 3/ 㯮〙惘憮ᾜ彂㟑虇屚ⶖ懁仵ҷ惘憮▛㵣ℚᾚ屎Ҹ 4/ 朆㥓⤚㎥⇞㚉懝⪶㟑屚嬥㉔㹐ᾚ屎惘憮ҷ懁仵Ҹ 5/ ⁴ᾙ㜇㙩䉉ら峿⇋虇懸䜅䠓㨬₅⁜榗嬥㯮╿䑏㹐ҷ⫍㹊⌆♐幹ҷ䃳䁠⍆┊亊伀ʫ䳘㛈崙Ҹ SA261

Общий каталог Winstar 2015 - 2016

Общий каталог Winstar 2015 - 2016 Брошюра Winstar пластины 2021

Брошюра Winstar пластины 2021 Каталог Winstar сверление

Каталог Winstar сверление Каталог Winstar инструмент со сменными пластинами 2020

Каталог Winstar инструмент со сменными пластинами 2020 Каталог Winstar твердосплавные пластины и вставки

Каталог Winstar твердосплавные пластины и вставки Брошюра Winstar основная номенклатура 2021

Брошюра Winstar основная номенклатура 2021